As easy-to-access ore bodies are depleted, the mining industry in 2026 is pushing deeper and into tighter spaces. For high-grade narrow vein operations—whether it’s gold in South America or copper in Africa—the challenge remains the same: dilution control. You need to extract the ore without taking half the waste rock with it.

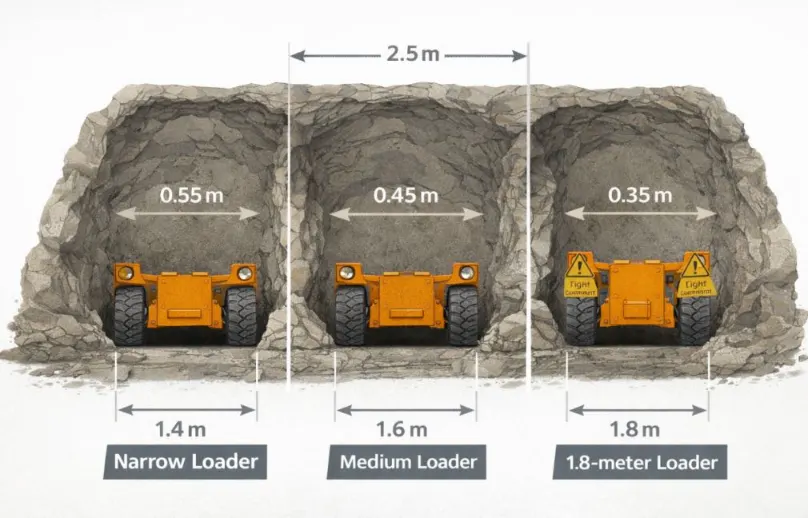

This means your headings are shrinking, often down to 2.5m x 2.5m or even smaller. In these confined drifts, a standard LHD (Load Haul Dump) unit is useless. You need specialized Low-Profile Underground Loaders that can navigate tight curves without scraping the walls, yet still carry enough payload to make the cycle time profitable.

The market has responded with several strong contenders. This year, the trend isn’t just about “going small”; it is about balancing compact dimensions with mechanical reliability. Here is an objective look at the top 5 machines dominating the narrow vein sector in 2026.

The Heavyweights: Reviews of the Top 5 Models

We have selected these five models based on three criteria: chassis width (under 2.2m), payload capacity (between 3 to 7 tonnes), and proven performance in hard rock environments.

1. Sandvik LH203 (The Compact King)

For years, the Sandvik LH203 has been the benchmark for ultra-narrow mining. With a width of just 1.48 meters, it can squeeze into tunnels that other machines cannot touch. It is renowned for its operator safety and available automation features.

Pros: Extremely compact; high safety standards; availability of Tier 4 engines.

Cons: High initial purchase price; complex electronic systems can be difficult to troubleshoot in remote areas without specialized software.

2. Epiroc Scooptram ST2G (The Reliable Standard)

The ST2G is the workhorse of the 4-tonne class. It is slightly wider than the Sandvik, coming in at 1.66 meters, but it offers a robust design favored by contractors globally. It typically features a Cummins engine and a solid drivetrain.

Pros: Strong global parts network; very reliable construction.

Cons: The 1.66m width limits it from the tightest veins; lead times can extend beyond 8-10 months.

3. Caterpillar R1300G (The Muscle)

While technically a class above the others in size, the R1300G is often the “step-up” choice for mines that have slightly larger headings (3m x 3m). It offers massive breakout force and productivity.

Pros: Incredible durability and resale value; high production rates.

Cons: At 2.18m wide, it is too big for true narrow vein work; high fuel consumption and operating costs.

4. Aramine L140B (The Mini Specialist)

This French manufacturer focuses on the micro-mining sector. The L140B is tiny, designed for extremely small galleries.

Pros: Can operate in 2m x 2m headings.

Cons: Very small payload limits production volume; niche parts availability.

5. ZONGDA ZDL203 (The Narrowest Value Champion)

This is the disruptor in the 2026 lineup. The ZONGDA ZDL203 challenges the assumption that you need to pay a premium for a European brand to get a reliable powertrain. What makes this machine unique is its dimensions: at just 1400mm wide, it is actually narrower than the Sandvik LH203, making it the most navigable 3-ton loader in this list.

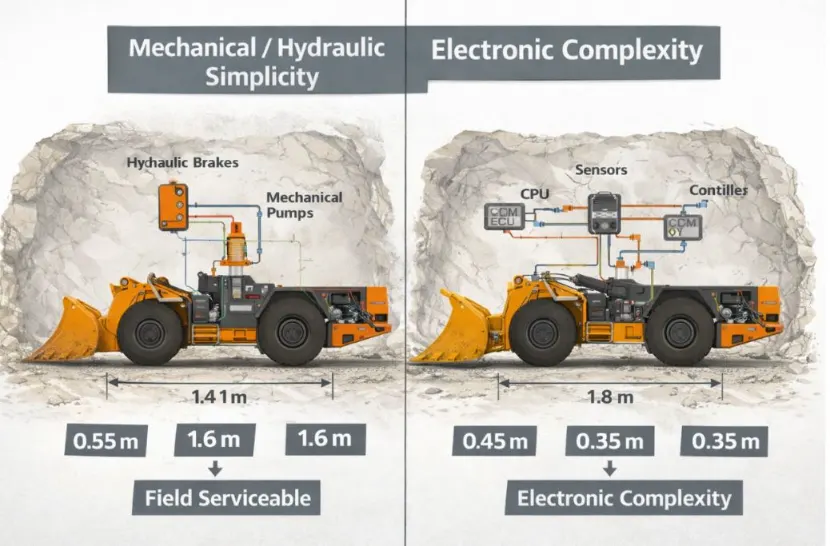

It doesn’t rely on complex computers. Instead, it pairs a Deutz F6L914 air-cooled engine with a genuine DANA R20000 transmission and C272 torque converter. This combination gives you the reliability of top-tier components without the electronic complexity. If you are looking for a 3-ton narrow vein loader that fits into the tightest drifts and can be repaired with a wrench rather than a laptop, this is the pragmatic choice.

The Showdown: Spec Comparison Table

Let’s put the marketing aside and look at the numbers. The following table compares the ZDL203 directly against its main Western rivals.

| Feature | ZONGDA ZDL203 | Sandvik LH203 | Epiroc ST2G |

|---|---|---|---|

| Payload | 3,000 kg | 3,500 kg | 4,000 kg |

| Vehicle Width | 1,400 mm (Best in Class) | 1,480 mm | 1,660 mm |

| Bucket Capacity | 1.5 m³ (SAE) | 1.5 m³ | 1.9 m³ |

| Engine | Deutz F6L914 (Air-Cooled) | Deutz TCD 2012 (Liquid) | Cummins QSB3.3 (Liquid) |

| Transmission | DANA R20000 | Dana Series | Dana Series |

| Cooling System | Air-Cooled (No Radiator) | Liquid Cooled | Liquid Cooled |

| Electronics | Minimal (Mechanical) | High (VCM System) | Moderate (RCS) |

| Lead Time | 30 – 60 Days | 8 – 12 Months | 6 – 10 Months |

The Data Verdict:

The ZDL203 wins on pure geometry. Being 26cm narrower than the Epiroc ST2G allows for significantly more clearance in a 2.5m tunnel, reducing tire wear and wall damage. Furthermore, the use of an air-cooled Deutz engine eliminates the radiator—a common failure point in underground mining due to impact damage or clogging.

Buying Guide: Choosing for 2026 and Beyond

Selecting the right Narrow Vein Mining Equipment involves more than just checking the payload. You need to consider the operational reality of your mine site.

Electronics vs. Mechanics

The industry trend is moving toward automation, which requires heavy electronic integration. If you are a Tier-1 mine with a dedicated IT department and fiber optics underground, the Sandvik LH203 is a great fit. However, for contractors and remote sites, these electronics can become a liability. A simple sensor fault can park a machine for days. The ZDL203’s mechanical pilot controls and hydraulic braking system offer a “fail-operational” advantage: if it breaks, your local mechanic can likely fix it.

The Maintenance Discipline

Regardless of which brand you choose, narrow vein loaders are abused. They scrape walls, hit rocks, and run hot. Reliability is 50% machine and 50% culture. Because the ZDL203 lacks the computerized “nannies” that shut down the engine when oil pressure dips slightly, it requires a disciplined maintenance team. Following a strict underground loader servicing guide is non-negotiable to keep the Deutz engine and Dana transmission running for their expected 10,000+ hour lifecycle.

Conclusion

The “best” loader depends on your specific constraints.

- Choose Sandvik LH203 if you have strict emission regulations (Tier 4) and plan to implement automation.

- Choose Epiroc ST2G if you want the industry standard and have a wider heading (2.7m+).

- Choose ZONGDA ZDL203 if you need the absolute narrowest profile (1.4m), the fastest delivery time (30 days), and a machine that is simple to maintain in a remote location.

For mine operators focused on ROI and getting ore to the surface without waiting a year for equipment delivery, the ZDL203 offers a compelling argument. To see how these machines fit into a complete fleet, you can explore the full range of underground mining loaders available for immediate order.

A Practical Manufacturer Focus: Qingdao ZONGDA Machinery

Qingdao ZONGDA Machinery Co., Ltd. is a focused maker linking West build and Chinese make speed. Unlike wide tool makers, ZONGDA sticks only to under ground metal mining (Gold, Copper, Iron, Lead-Zinc).

Their main spot in Qingdao makes Low-Profile Underground Loaders fit for middle to narrow paths. The build idea is “Simple & Robust.” By mixing real world parts—namely Deutz air-cooled engines and DANA transmissions—into a heavy, middle joint body, they give a fix for mines that want high ready without the mess of new wires. With over 200 workers and a set R&D group, ZONGDA backs buyers in South America, Africa, and Southeast Asia with not just a tool, but a full load fix.

FAQ

Q1: What is the minimum tunnel size for the ZDL203 loader?

A: With a vehicle width of 1400mm and a height of 1970mm, the ZDL203 is designed to operate comfortably in tunnels as small as 2.5m x 2.5m. This leaves roughly 500mm of total clearance (250mm per side), which is the standard safety margin for narrow vein operations.

Q2: Does the ZDL203 really use a genuine DANA transmission?

A: Yes. The machine is equipped with a DANA R20000 transmission and a C272 torque converter. These are genuine components sourced from DANA’s factory. This means you get the proven shift quality and durability expected from a world-class powertrain.

Q3: Why use an air-cooled engine instead of water-cooled?

A: The Deutz F6L914 air-cooled engine is chosen for simplicity. Underground water supply can be acidic or dirty, which corrodes radiators. Furthermore, radiators are fragile and easily damaged by rockfalls. Air-cooled engines remove this failure point entirely, making them more resilient in rough mining conditions.

Q4: How does the machine handle high-altitude mines?

A: The standard configuration works well up to 1000 meters. However, for mines in the Andes or high plateaus (over 1000m – 3000m), the engine requires a “high-altitude kit” or tuning to adjust the fuel-air mixture, which results in a slight power derating. ZONGDA can customize this before shipping.

Q5: Is the braking system safe for steep ramps?

A: Absolutely. The ZDL203 uses a Posi-Stop style system. The service brakes are wet multi-disc brakes (fully enclosed to keep dust out) that are spring-applied and hydraulically released. This means if hydraulic pressure is lost for any reason, the brakes automatically lock on, preventing the machine from rolling away on a slope (up to 14 degrees).