The whole underground mining industry is changing-featuring new technologies, new safety standards, and greater demands for efficiency and environmental responsibility. This transformation can be clearly seen in the type of locomotives used for material haulage and for moving miners within the mine tunnels.

This blog will explain the current debate between electric and diesel underground mining locomotives, describe the pros and cons of each, and finally present solutions developed by Qingdao Zongda Machinery Co., Ltd., a world leader in underground mining locomotives, to better illustrate how newer electric options are better suited to the growing expectations of the sector.

The Trend Towards Electric Underground Mining Locomotives

Generally, electric locomotives are cleaner and more viable compared to diesel locomotives due to zero emissions and lessened environmental impact. These locomotives operate on battery or overhead electric systems, thus finding their applications in environments where diesel exhaust fumes might seriously compromise the health and safety of miners or contaminate the air. In fact, a report by Frost & Sullivan noted that the shift to electric mining equipment is necessary to comply with future regulations on air quality and emissions in underground mining operations.

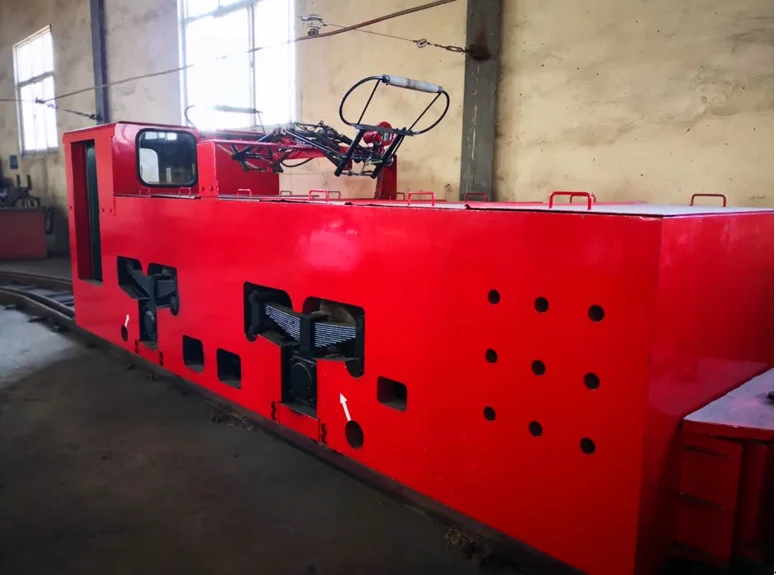

For instance, Qingdao Zongda Machinery Co., Ltd., a leading manufacturer in this field, provides electric underground mining locomotives like the CJY14/610 G250, a 14-ton trolley electric locomotive designed for large mining operations. The one under discussion, with the energy-saving IGBT stepless speed regulation, is highly ideal to reduce costs and minimize emission simultaneously. This locomotive is highly agile, minimum turn radius, for building in grueling environments as well. Added to this advantage is the option of operating battery electric locomotives by Zongda in explosion-proof environments when the importance is on safety.

Diesel Underground Mining Locomotives: The Workhorse of old

Even though electric locomotives are gaining ground, diesel-powered locomotives are still in use in most underground mining operations. For long, diesel locomotives have been the industry standard due to their reliability, high power output, and easy fueling. These are usually preferred in mines where electrical infrastructure is not sufficient or where the cost of setting up an electric-powered system is high.

Diesel locomotives are also flexible in terms of range and operating time. Diesel locomotives can operate for a long time without needing a recharge, unlike electric locomotives, which rely on battery charging or constant electrical supply, making them ideal for long-distance transport within mines. It is, however, done at the cost of environmental sustainability as diesel engines release harmful gases that include carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter that harms the workers’ health and the environment simultaneously.

Key differences between electric and diesel underground mining locomotives

1. Environmental impact

The most important positive aspect of the electric locomotives compared with diesel is its environmental friendliness. Diesel is one of the worst air-polluting devices. In subterranean mine settings, air quality is often significantly affected, leading to serious safety problems. Diesel generates CO2 and carbon monoxide and particulate matter, which tend to congregate in limited spaces such as tunnels.

Contrasting that, the direct emissions by electric locomotives do not occur, and their existence has led to reduced carbon footprints associated with mining and enabled them to fulfill more demanding environmental regulations. Their shift is inline with international sustainable drives while considering international accords, such as the Paris Agreement, targeting global emission reductions to 50% of current emissions levels by the year 2030.

The Qingdao Zongda CJY14/610 G250 trolley electric locomotive is not only an environment-friendly product but also designed with energy-saving technologies to ensure that relatively low operational costs are ensured. With such corrosion-resistant design and stable operation, the train supports green mining projects which put in both eco-friendliness and high performance at once.

2. Operational Costs and Efficiency

Electric locomotives are, on average, less expensive than their diesel-powered counterparts in total cost of ownership. Although higher upfront investment for electric locomotives is involved to set up infrastructure such as charging stations or overhead lines, running costs are lower for electric locomotives. Electric locomotives use electricity, which is generally more economical than the price of diesel, and their parts are few, reducing their frequency and hence the cost of replacement.

For instance, Zongda’s battery electric locomotives, including the CTY8/610GB110 model, have strong traction with efficient power consumption and a simple mechanical gearbox. These are particularly suited to mines that have explosion-proof requirements and provide good service with a lower cost of operations in the long term. Also, they have fewer mechanical parts, which is simpler to maintain, thus lower downtime and longer life.

On the other hand, diesel-powered locomotives are usually more costly to maintain since their engines and fuel systems are highly complex. Besides, diesel engines require periodic servicing for optimal performance, which contributes to higher maintenance costs.

3. Performance and Power Output

While diesel locomotives often provide more raw power and greater operational range, modern electric locomotives are rapidly closing the performance gap. Electric models now have comparable speed and traction force with many models including advanced technologies to enhance efficiency and reduce energy consumption.

For example, the Zongda CJY14/610 G250 electric locomotive has an hour rated traction force of 26.68 kN and a structural speed of 27 km/h. Such values suggest that electric locomotives can satisfy the performance needs of large mines as they can provide high power as well as energy efficiency in one package.

Future of Mining Locomotives: What’s Next in 2025?

Future increases are anticipated in electric locomotives, as even more mining firms minimize their harmful environmental impact, complying with demanding emission standards. By 2025, electric underground mining locomotives will still dominate the market, and with this, more innovative and low-cost solutions such as offered by Qingdao Zongda Machinery Co., Ltd. can be expected in the market.

Zongda’s electric locomotives, such as the CJY14/610 G250 trolley locomotive and the CTY8/610GB110 battery electric locomotive, are the new benchmark for performance, safety, and sustainability in underground mining. These solutions can help mining companies not only increase their operational efficiency but also contribute to making the industry cleaner, safer, and more sustainable.