All You Need to Know About Underground Mining Trucks

What Are Underground Mining Trucks?

Underground mining trucks are tough machines built to roll through the wild conditions of deep mines. They haul ore, rocks, and other stuff from dig sites to processing spots or up to the surface. Unlike regular mining trucks, these bad boys are made for squeezing through tight tunnels and climbing steep slopes while keeping things safe and speedy. Cool, huh?

Key Features That Make Them Tick

These trucks come loaded with tricks for underground work. They’ve got bendy frames that twist and turn easy, four-wheel drive for killer grip, and hydraulic steering to glide through narrow spots. Safety’s big too—many rock wet multi-disc brakes with hydraulic release for quick stops. Take the ZDT210 Underground Mining Truck: it’s got a Deutz water-cooled engine that’s low on fumes and a DANA gear system for smooth, tough runs. Built to last, no doubt!

Why They’re a Big Deal in Mining

In mines, these trucks are game-changers. They zip materials around fast, cutting downtime and saving cash on labor. Their rugged builds handle crazy conditions like wet air, dim light, and bumpy ground. With trucks like these, mines keep humming along. Who wouldn’t want that?

Types of Underground Mining Trucks

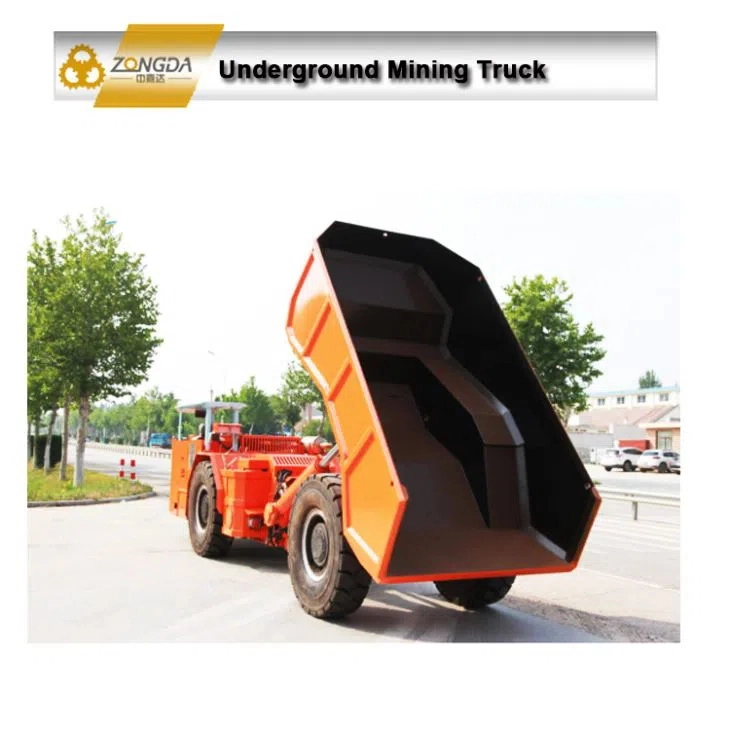

Dump Trucks for Underground Gigs

Underground dump trucks have back-end buckets that make dumping a breeze in tight spots. The ZDDK-20, a 20-ton beast, rocks a bendy frame and double-cylinder lift for easy unloading. Perfect for hauling big loads of ore or debris without a hitch.

Low-Profile Trucks for Tight Tunnels

Low-profile trucks are short and stout, built for tunnels with low ceilings. They’re small but mighty, carrying solid loads through skinny passages without missing a beat. Gotta fit in those cramped spaces, right?

Articulated Trucks for Twist-and-Turn Jobs

Articulated trucks have hinged frames that let ‘em snake through tight curves. The ZDT105 is a star here, with hydraulic transmission and a tight turning radius for mid-sized tunnels. They’re like the gymnasts of mining trucks—super flexible!

Why Underground Mining Trucks Rock

Speedy Work and Big Wins

These trucks crank up productivity by moving stuff fast. Compared to old-school methods, they save tons of time. With strong engines and tough transmissions, they handle heavy loads like champs, keeping the mine’s flow steady.

Safety Stuff Built Right In

Safety’s non-negotiable underground. These trucks pack features like spring brakes, hydraulic release systems, and strict operator rules. For example, the ZDT845 needs drivers to wear helmets and carry self-rescue gear. That’s keeping miners safe, big time!

Tough Enough for Anything

Built like tanks, these trucks laugh off harsh conditions. High-quality parts and cutting-resistant tires keep ‘em rolling through wet, rough tunnels. Bendy frames boost grip, and models like the ZDT845 stay stable no matter what. They’re ready for any challenge.

Picking the Right Underground Mining Truck

Size and Load Smarts

Choosing a truck means checking its load size and fit. These machines gotta squeeze through tunnels while hauling big weight. The ZDDK-20 handles 20 tons and fits tunnels ≥4.5×4.5 meters. The ZDT315 is another heavy hitter for bigger jobs. Match the truck to your tunnel, or you’re stuck!

Fuel Use and Green Vibes

Fuel’s a big deal—saves money and cuts down on fumes. Diesel trucks like the ZDT210 and ZDT845 use Deutz engines that sip fuel and spit out less pollution. That’s good for costs and the planet. Picking green trucks helps mines meet eco-rules while keeping the air cleaner underground.

Keeping ‘Em Running Smooth

Maintenance keeps trucks safe and ready. The ZDT210, for instance, needs regular checks, helmets, and self-rescue gear for operators. Hydraulic systems and brakes like wet multi-disc ones need pro servicing to stay sharp. A little TLC goes a long way in a mine.

New Tech Making Trucks Even Cooler

Electric Trucks for Cleaner Rides

Electric mining trucks are shaking things up. They ditch diesel fumes, making air quality better in tight tunnels. While not listed for models like ZDT210, electric options are trending in mining for lower costs and zero emissions. Cleaner mines, happier workers—win-win!

Automation and Remote Control Magic

Automation’s a big deal now. Some trucks let operators drive ‘em from a safe spot using remote controls. That cuts risks and boosts precision when moving loads. It’s like playing a high-stakes video game, but for real mining work. Safety and smarts in one!

Fancy Materials for Tougher Trucks

New materials make trucks last longer and work better. Cutting-resistant tires and hinged frames, like on the ZDT845, boost grip and toughness. These upgrades let trucks handle rough ground and heavy loads without breaking a sweat. Built to endure, no question.

FAQs

- What should I think about when picking a mining truck?

Look at load size, tunnel fit, fuel use, eco-impact, and upkeep needs. - How do electric trucks help underground?

They cut fumes, save cash, and keep air cleaner in cramped spaces. - What safety stuff do these trucks have?

Think brakes, operator rules like helmets, and regular check-ups. - What’s new with mining truck tech?

Automation, remote controls, and tough materials are changing the game.

For custom gear or more info, reach out to QINGDAO ZONGDA MACHINERY CO., LTD. or check their site for the latest on their slick equipment!