Introduction: Heavy-Duty Mining Trucks are the Backbone of Underground Mining

Few activities around the planet can be said to be as extreme as underground mining operations. Of these, mining trucks play a very major role since they operate in transporting ore, wastes, and materials. These face rough grounds, severe climatic conditions, and heavy loads while the demands for operational efficiency and safety keep on increasing.

The present paper entered the industry of underground mining trucks, which are radical changes discussed with top brands in the business, checking on their key features and performance metrics-so long as their contributions to productivity, safety, and cost-effectiveness are all taken into account. We will give a highlight of how companies like Qingdao Zongda Machinery Co., Ltd. is driving ahead with highly advanced solutions using underground mining trucks, providing optimal performances today.

With unceasing demands for minerals across the globe, the need for mining trucks that are very strong, efficient, and highly functional is something that is on the rise. In 2023, the World Bank predicted that the demand for metals like copper, lithium, and cobalt would rise by more than 50% until 2030, which will further raise pressure to optimize mining operations in regard to fleet company performance, including underground mining trucks designed to bear the burden of increased load and demand.

Why Underground Mining Trucks Are Crucial to Success

Underground mining trucks are designed to transport very heavy loads, sometimes up to several tons of material, in cramped and usually hazardous conditions. Unlike surface mining, where the trucks drive over expansive open land, underground mining trucks drive through narrow twisting tunnels and sharp inclines. The basic tasks of these trucks include:

Hauling ore and other mined materials to the surface or processing facilities

Waste removal from excavation sites

Transporting equipment and tools to inaccessible mine areas

Herein, the reliability, power, and design of the mining trucks help reduce down time while improving safety and increasing productivity. In these regards, selection of appropriate truck brands is paramount in ensuring ideal results in mining exercises. In consideration, let’s look at some of the premier brands known for their ultimate underground mining trucks.

Top Brands in Underground Mining Trucks

1. Caterpillar: Ruling with Durability and Versatility

Caterpillar has to be one of the most recognizable names in heavy machinery, and its line of underground mining trucks is no exception. The Cat® AD60 underground mining truck is for high efficiency, optimum productivity, and long life.

Key Features:

Payload Capacity: 60 tonnes

Powerful Engine: Powered by a C15 ACERT™ engine that assures very good fuel efficiency and low emissions.

Advanced Hydraulics: Advanced hydraulic suspension system provided by Caterpillar for smooth handling even on the most uneven and rough ground.

Safety Features: The truck is fully equipped with safety features, including anti-slip steps, fire suppression systems, and ROPS/FOPS cab protection.

Caterpillar’s underground trucks are known to be rugged, fuel-efficient, and can manage steep gradients with heavy payloads, making them among the favored choices for large mining operations worldwide.

2. Volvo Construction Equipment: Efficiency and Sustainability

Volvo has been leading the race for mining truck technology, ensuring that their trucks are not only strong and long-lasting but also economic on fuel and environment-friendly. The Volvo A60H articulated hauler for extreme mining conditions promises top performance with minimum environmental impact.

Key Features:

Payload Capacity: 55 tonnes

Fuel Efficiency: The Volvo A60H features excellent fuel efficiency with the strong Volvo D16J engine.

Technology Integration: Incorporates Volvo’s Load Assist technology, which allows operators to monitor real-time loading and unloading for better efficiency.

Safety and Comfort: High-visibility cab, advanced ergonomics, enhanced suspension system for operator comfort.

At Volvo, the commitment to sustainability is reflected in engine technologies, aside from the use of hybrid powertrains on some models, ensuring mining companies meet their productivity requirements while maintaining environmental standards.

3. Komatsu: Strength and Reliability in Challenging Environments

Komatsu is a leading company in the manufacture of construction and mining machinery. This firm produces very strong underground mining trucks, which could bear some kind of harsh conditions. The Komatsu HM400-5 articulated dump truck has been designed to easily carry massive loads on hard, uneven terrain.

Some Key Features:

Payload: 40 tons

Powerful engine performance: It is facilitated by a Komatsu SAA6D140E-5 for great torque and less fuel consumption. Advanced suspension to provide stability and comfort, even on uneven surfaces, with the truck. Operator-friendly design: The cabin provides relentless visibility and a host of the latest safety features, including an air filtration system.

The underground trucks from Komatsu have earned world-wide reputation for their high dependability and durability coupled with effective performance and operational simplicity. Thus, a mining company never feels disgruntled over the services sought for long-term dependable use.

4. Sandvik: Innovative Mining Solutions

Sandvik is a global supplier of mining and rock excavation equipment, intelligently creating solutions based on deep knowledge, serving a wide array of mining trucks for all underground operations. The Sandvik TH663i is one of the most advanced models produced by the company; it combines in one package power, versatility, and low cost of ownership.

Key Features:

Payload Capacity: 60 tonnes

Fuel Efficiency: The TH663i has been engineered for optimal fuel efficiency in order to help reduce the total cost of ownership.

Intelligent Automation: With the Sandvik OptiMine® system for real-time performance monitoring and fleet management.

Ergonomically Designed Cabin: For comfort and safety of the operators, equipped with high-quality air filtration and noise-reduction systems.

Sandvik’s underground mining trucks are built for productivity, utilizing the latest in advanced technology to enable automation and real-time data analytics.

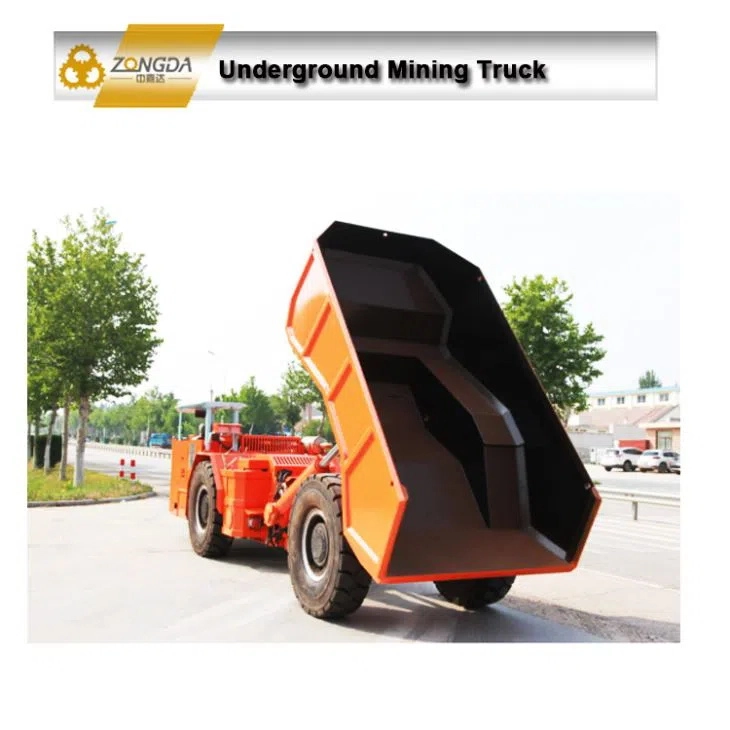

Why Choose ZONGDA for Underground Mining Trucks?

With international brands such as Caterpillar, Volvo, Komatsu, and Sandvik already dominating the underground mining truck market, Qingdao Zongda Machinery Co., Ltd., popularly known as ZONGDA, has been closing the gap pretty fast for its unstoppable value, performance, and customization options in underground mining equipment.

ZONGDA trucks mine for gracing tough mining environments and hence assure the best class on durability, power, and fuel efficiency. Among others, their 70 Ton Underground Mining Dump Truck HOWO 6X4 features astonishing features to meet the Mining operation effectively.

Basic Features of Mining Trucks, ZONGDA

Rated Load : 20 tonnes

Engine Options:DEUTZ F12L413FW or VOLVO TAD853VE

Advanced Hydraulic System: The hydraulic system assures safety and durability for easy operations.

Heavy-Duty Build: It is designed to travel in tunnels with dimensions ≥4.5×4.5m.

Climbing Capacity: A capacity of 15° slope provides it with steep gradients that normally characterize underground mining.

High Performance: The truck assures a speed of 30.9 km/h, making it very suitable for fast transport of materials over long distances in big mines.

Customization and Cost-Effectiveness ZONGDA mining trucks have great potential for customization in order to satisfy the requirements for specific payload capacities, varied configurations of engines, and varied terrain adaptability. Since the company has strong design and enforcing production standards, the technology ensures that its trucks can bear the hard task requirements arising in modern mining at cost-effective levels.

With over 10 years of experience in the mining industry, ZONGDA has built a reputation for producing high-quality, reliable equipment at competitive prices. Their commitment to providing excellent after-sales service ensures that mining companies can maximize the performance and lifespan of their equipment.

Conclusion: The Road Ahead for Underground Mining Trucks

The demand for high performance, durable, and energy-efficient underground mining trucks will keep on increasing with rising mining operation complexity. A few leading companies like Caterpillar, Volvo, and Komatsu have been incorporating features in the underground mining trucks with a focus on increasing the productivity, ensuring better safety, and reducing the overall operations costs. However, companies like ZONGDA have created their niche by offering low-cost solutions and customizing as per ever-evolving industry demands.

In that light, mining companies consider many aspects-like payload capacity, fuel efficiency, the inclusion of all sorts of safety features, and operating costs with regards to maintenance-when opting between underground mining trucks. Indeed, ZONGDA has a line of mining trucks best suited for business operations optimizing needs at the mines underground.

In this blog, it goes up by showing Qingdao Zongda Machinery Co., Ltd., its mining trucks, and their capabilities; it does an excellent job of making an evident CTA for the customers so that they could go well with.