Understanding the Role of Mining Trucks in Modern Mining Operations

The Importance of Mining Trucks in Open-Pit Mines

Mining trucks are vital to today’s mining activities, especially in open-pit mines. These sturdy vehicles are crucial for moving huge amounts of dug-up materials like ores, minerals, and waste rocks. Their capacity to carry heavy loads effectively keeps mining operations productive and profitable. Using mining trucks ensures that materials travel safely and swiftly from dig sites to processing plants or waste zones.

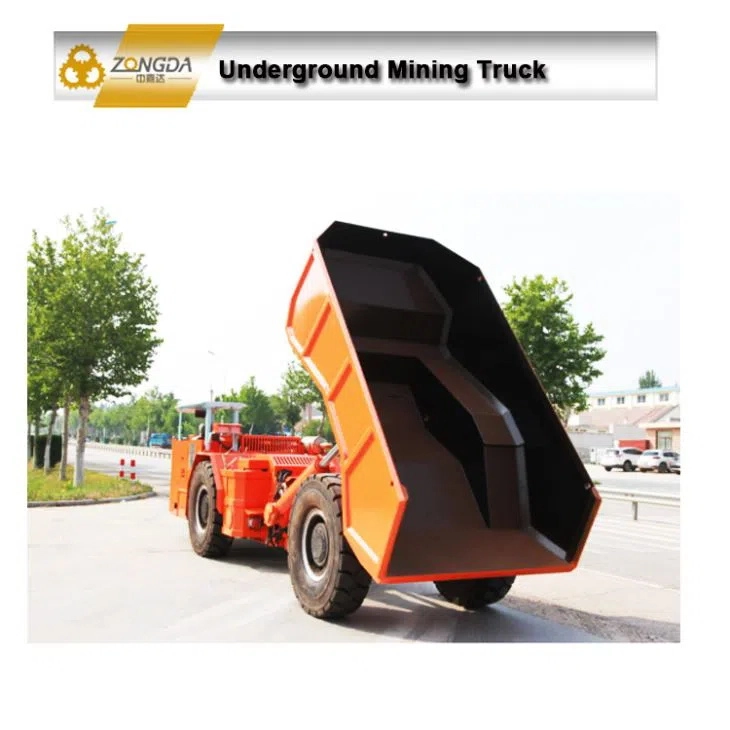

The build and features of mining trucks are crafted to endure tough mining conditions. Take the ZDT210 Underground Mining Truck as an example. It boasts a strong power setup with a Deutz water-cooled, low-pollution engine. It also has hydraulic mechanical transmission and four-wheel drive abilities. The frame uses a central hinged rotary design. This improves how well the whole machine grips the ground. Such traits boost the dependability and flexibility of mining trucks in rough landscapes.

Challenges Faced by Conventional Engine-Driven Mining Trucks

Even though they’re essential, traditional engine-powered mining trucks encounter several hurdles. A major problem is their dependence on diesel engines. This leads to high fuel use and exhaust fumes. Not only does this raise running costs, but it also sparks environmental worries due to greenhouse gases.

Moreover, conventional mining trucks often face energy waste during use. Uneven ground, constant braking, and changing loads can cause excess energy loss. upkeep needs for these trucks also tend to be greater. Wear and tear on parts adds to the challenge.

Introduction to Hybrid Power Systems in Mining Trucks

What Are Hybrid Power Systems?

Hybrid power systems blend two or more energy types to run a vehicle. For mining trucks, they usually pair a standard diesel engine with an electric energy storage unit, like batteries or supercapacitors. This mix enhances energy efficiency. It adjusts power use based on what the job demands.

Hybrid setups aim to overcome the drawbacks of fully engine-driven trucks. They cut fuel use and emissions while boosting overall output. Advanced energy management tactics help achieve this. They balance how multiple power sources are used.

Key Components of Hybrid Energy Storage Systems (HESS)

Hybrid Energy Storage Systems (HESS) form the heart of hybrid power options for mining trucks. These systems include vital parts such as:

- Batteries: Batteries act as the main energy holder in HESS. They supply steady power for long stretches. They’re perfect for consistent tasks.

- Supercapacitors: Supercapacitors work alongside batteries. They provide quick surges of power during high-need moments, like speeding up or lifting heavy loads.

- Energy Management System (EMS): The EMS oversees how batteries, supercapacitors, and other truck parts interact. It ensures energy is shared out effectively.

By combining these elements, HESS allows mining trucks to run more smoothly. It also cuts down on energy waste.

Benefits of Hybrid Power Systems for Heavy-Duty Vehicles

Switching to hybrid power systems brings many perks for heavy-duty rigs like mining trucks:

- Less Fuel Use: Hybrid setups make smarter use of fuel. They tap electric power during low-need tasks.

- Fewer Emissions: By leaning less on diesel engines, hybrid trucks release fewer greenhouse gases.

- Better Output: Pairing batteries with supercapacitors ensures steady power, even in tough situations.

- Cost Reductions: Lower fuel use and fewer repairs mean savings over time.

For instance, the ZUPC-16 Personnel Carrier features smart ergonomic designs and tough build parts. This shows how new ideas improve safety and efficiency alike.

Innovations in Energy-Saving Control Frameworks for Mining Trucks

Minimizing Energy Dissipation with Optimized Energy Flow Control

A key aim in designing hybrid mining trucks is cutting energy waste. Optimized energy flow control focuses on sharing power wisely across truck parts. It bases this on real-time job needs. This curbs unneeded energy loss during tasks like braking or sitting idle.

Smart control formulas are vital here. They keep an eye on how the truck performs. Then, they tweak energy sharing as needed.

Model Predictive Control (MPC) for Battery and Supercapacitor Distribution

Model Predictive Control (MPC) is a fresh method used in hybrid systems. It handles how batteries and supercapacitors share power well. MPC uses forward-thinking formulas to guess future power needs. It bases this on current conditions.

By predicting energy demands, MPC ensures batteries take on long, steady loads. Meanwhile, supercapacitors tackle short, sharp spikes. This teamwork boosts efficiency and keeps HESS parts lasting longer.

Electro-Hydraulic Decoupled Torque Distribution Strategies

Electro-hydraulic decoupled torque distribution methods mark another leap in hybrid truck tech. These approaches allow exact control over torque delivery. They separate hydraulic systems from mechanical drivetrains.

This split offers more wiggle room for torque changes. It adjusts based on load and ground conditions. The result? Smoother running and less strain on parts. Plus, it improves grip control. This matters a lot on uneven or slick mine surfaces.

Environmental and Economic Benefits of Hybrid Power Systems in Mining Trucks

Reducing Carbon Emissions with Zero-Emission Solutions

Hybrid power systems in mining trucks are transforming the field. They sharply cut carbon emissions. These setups mix diesel engines with advanced energy storage, like batteries and supercapacitors. This optimizes energy use. By using electric power for low-demand tasks, hybrid trucks rely less on diesel. That means fewer greenhouse gas emissions.

This shift is key for mines aiming to meet tough environmental rules and sustainability targets. Take the ZDT210 Underground Mining Truck. It uses a Deutz water-cooled, low-pollution engine. This tech boosts performance while supporting greener goals. Hybrid trucks with energy recovery can also grab power made during braking or downhill runs. They store it for later use. This cuts fuel use and emissions even more.

Zero-emission options in hybrid mining trucks also meet rising calls for eco-friendly mining practices. They blend renewable energy and smart control formulas. This leads to a cleaner environment without sacrificing work efficiency.

Enhancing Fuel Economy and Lowering Operational Costs

Fuel savings are a big deal in the costly mining world. Hybrid power systems greatly improve fuel efficiency. They smartly split power between diesel engines and electric parts. During low-power times, like idling or light loads, the system flips to electric mode. This saves fuel.

The ZUPC-16 Personnel Carrier, for example, uses advanced ergonomic designs. These improve efficiency while keeping operators safe and comfy. Hybrid systems also ease wear on mechanical bits. They spread torque better across truck parts. This means less upkeep and longer-lasting components.

Lower running costs are another plus of hybrid mining trucks. Less fuel use cuts expenses directly. Reduced repair needs add more savings. These benefits make hybrid systems a smart choice for mining firms aiming to boost profits while staying eco-conscious.

Future Trends in Hybrid Power Systems for Mining Applications

The future of hybrid power systems rests on steady progress in battery and supercapacitor tech. High-capacity batteries are in the works. They aim to hold more energy in smaller sizes. This suits heavy-duty uses like mining trucks. These batteries promise longer work cycles and quicker charging. That means less downtime on the job.

Supercapacitors back up batteries by giving fast power bursts during high-need moments, like speeding up or heavy lifting. New efforts aim to boost supercapacitor energy density. Yet, they’ll still deliver instant power. This pairing ensures hybrid mining trucks handle changing loads well.

Take Scooptram Mining equipment as an example. Its hydraulic mechanical transmission shows how advances lift performance and adaptability in tough settings.

Looking ahead, solid-state batteries are coming into play. They offer higher safety and better heat stability than standard lithium-ion batteries. These steps will make hybrid power systems more trustworthy and efficient for mining tasks.

Frequently Asked Questions

How do hybrid power systems improve mining truck efficiency?

They make energy use smarter. They combine diesel engines with electric storage, like batteries or supercapacitors. This cuts fuel use and emissions.

What are the environmental benefits of hybrid mining trucks?

They release fewer greenhouse gases. That’s thanks to less diesel reliance. Energy recovery systems also boost sustainability.

What advancements are expected in battery technology for mining applications?

High-capacity solid-state batteries are coming. They’ll offer longer cycles, faster charging, better safety, and improved heat stability.

How does AI contribute to hybrid system efficiency?

AI tracks truck performance in real time. It optimizes energy sharing with predictive formulas like MPC. It also aids predictive upkeep plans.

To explore cutting-edge options or customization services from QINGDAO ZONGDA MACHINERY CO., LTD., reach out to us today!