In high-utilization underground mines, underground mining trucks sit inside the production heartbeat. When one unit drops out, the ripple travels fast. The loader starts waiting for empty trucks. The dump point backs up. Operators change habits to “keep things moving,” and cycle time drifts before anyone calls it a problem.

A servicing plan for mining trucks keeps haulage steady when the mine is running hard. It is not a checklist pinned to the workshop board. It is a working plan tied to how your trucks actually travel, how your headings behave, and how your shifts move ore. If steady tonnage matters, your underground mining truck maintenance plan has to follow real duty, not a neat calendar.

Why Traditional Maintenance Schedules Fail Underground

Most standard schedules assume conditions stay roughly the same. Underground, they do not. Heat builds near faces. Dust loads change after blasting. Water appears in places that were dry last month. Access stays tight, and “quick checks” get skipped because the bay is full or the crew is already chasing a breakdown.

Calendar-based plans often look fine on paper and fall apart in the first few weeks. Even hour-based intervals can miss what really drives wear in ramps and hot headings. If trucks spend shifts on steep grades, brake and driveline stress climbs fast. If they spend shifts queuing, engines idle longer, cooling airflow changes, and electrical loads behave differently. Your mining truck servicing plan has to track duty patterns, not dates.

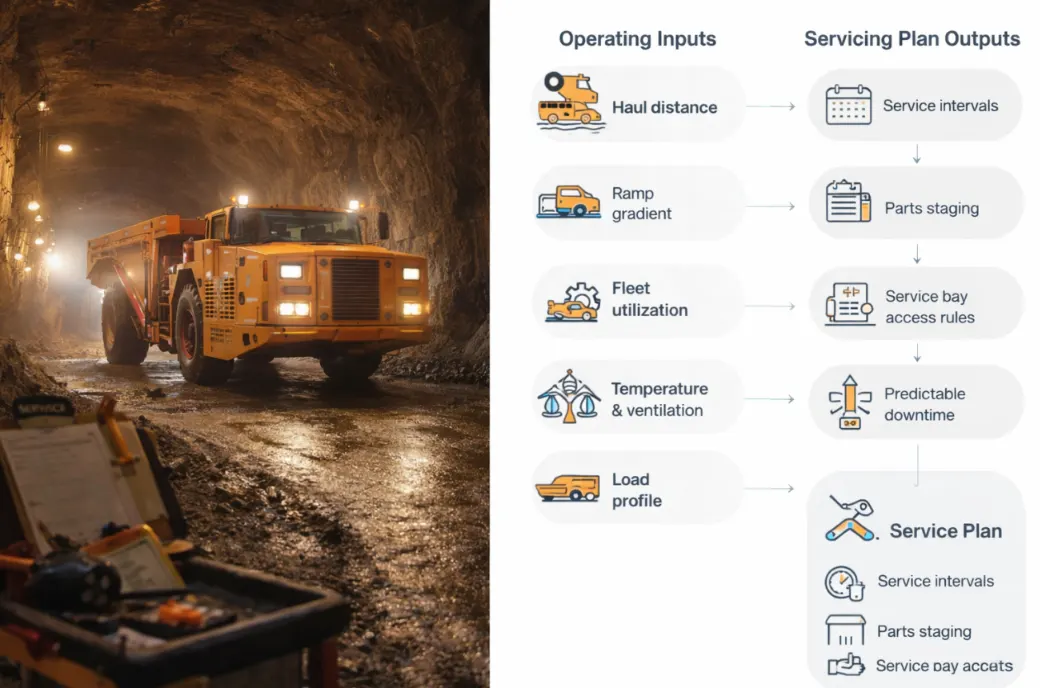

Key Operating Variables That Shape a Servicing Plan

Before you set intervals, lock down the variables that push wear and failures underground. People sometimes treat this as “context,” then rush to tasks and service hours. That shortcut costs you later. These inputs decide whether the plan holds up during high production weeks or gets ignored the first time the schedule slips.

Treat the list below as the “front page” of your underground truck maintenance planning. When one of these inputs changes, service priorities should move with it.

Haul Distance and Ramp Gradient

Haul distance sets the baseline workload. Ramp gradient decides how that workload hits brakes, driveline, and cooling. A short route with a steep decline can punish brakes more than a longer route on gentle grades. If your ramps force frequent braking, tighten checks around brake wear, brake temperature behavior, and fluid condition. Retarder use matters as well, because it shifts where heat builds and how quickly components cool back down.

Track specific ramp segments, not only an average gradient. One sharp corner or one long downhill section can drive most of your brake heat. That is often where pads disappear early and operators quietly change driving style to cope.

Truck Utilization Rate and Shift Patterns

High utilization usually means two or three shifts and short changeovers. That improves output, but it shrinks service windows. If service time is always “later,” later does not arrive. Then reactive maintenance lands in the middle of peak production, which is the worst time to lose a truck.

Build your plan around actual hours of operation per day, plus how often trucks sit in queues. Queuing still counts. Engines idle, vibration keeps working on mounts and wiring, and cooling fans live in a different world than they do on open roads. If utilization is high, schedule small checks more often and keep them short. Ten minutes that actually happens beats a “two-hour service” that never gets a slot.

Ambient Temperature and Ventilation Conditions

Underground temperature is not surface temperature. Ventilation patterns change as development moves and airflow gets adjusted. Hot headings shrink cooling margins, and problems show up slowly at first: more coolant top-ups, hoses that age faster, fan drives that start to sound “a bit off,” and operators reporting heat alerts more often.

Add simple triggers to your underground mining truck maintenance plan. For example, if coolant top-ups rise over a week, move up inspections on hoses, clamps, radiator cores, and fan drives. Nobody brags about catching a tired clamp early, but it saves long stops later.

Load Profile and Duty Severity

Rated payload does not describe real loading. Actual load profile swings with fragmentation, bucket fill, and operator behavior. Oversize rock adds shock loads. Wet muck changes rolling resistance. A truck can stay “within payload” and still get punished by the material it hauls and how it is loaded.

If duty is severe, put extra attention on articulation joints, suspension components, frame stress points, and tire condition. Underground truck maintenance that ignores duty severity ends up chasing failures rather than preventing them.

Linking Cycle Time to Service Intervals

Cycle time is not only a production number. It is a wear pattern repeated hundreds of times. Each cycle adds braking events, acceleration events, steering articulation, and vibration. When cycle time stretches because of congestion or a slow dump interface, trucks idle more and run hotter in awkward ways. That shifts stress toward cooling, electrical load, and engine idle behavior.

Start by mapping a normal cycle time range for each route. Then tie certain service checks to cycles or duty blocks, not only engine hours. Brake checks often track better with braking intensity and frequency than with hours. Hydraulic leaks often track with heat and repeated articulation. Small signals matter. If loading time rises and trucks stack up, check haulage bottlenecks because that change also changes how the truck wears. This links back to underground mining trucks in daily haulage operations across the underground haulage system.

One practical habit helps: when cycle time shifts by a meaningful amount and stays there for a week, treat it like a service trigger. That is often the moment when “planned” can stay planned, instead of turning into weekend firefighting.

Planned Servicing vs Reactive Maintenance Underground

Reactive maintenance is not just expensive. Underground, it is disruptive. A breakdown can block traffic. Towing takes time. Ventilation and safety steps slow everything. Crews may lose half a shift just setting up access, lighting, and clearance. Then the job stalls because the right part is not on site, and the “simple fix” becomes a long outage.

Planned servicing is about predictability. You choose the time and place. You control the job scope. You stage parts. Downtime stays smaller and easier to absorb. In high-utilization underground mines, the best setup is often a mix of small, frequent jobs that fit real windows, plus fewer deep services that require downtime planning.

Put it in plain terms: the goal is not a fantasy where nothing fails. The goal is to stop failures from landing on your busiest day, in your tightest drift, when the radio is already full of problems.

Servicing Access, Spare Parts, and Underground Constraints

Underground servicing is shaped by space and logistics. Service bays fill up. Tools travel. Parts move slowly when cage schedules are tight. Even simple work can stall if the truck is parked in a bad spot or the bay is shared with other equipment.

Build the plan around access first. Define where inspections happen, where light service happens, and where heavy service happens. Then set rules that people can follow under pressure. No heavy service in a traffic lane. No “quick fix” that turns into two hours with the truck half blocking a ramp. It sounds strict, but it keeps the mine moving.

Spare parts planning belongs inside the servicing plan, not on a separate spreadsheet nobody checks. Identify the parts that cause long downtime when missing: brake components, hoses, filters, belts, common sensors, and key electrical connectors. Set minimum stock levels tied to utilization and lead time. If a part takes three weeks to arrive, it cannot be treated like a nice-to-have. That is how a minor leak turns into a month of headaches.

Labor planning matters too. Underground work needs coordination. If your plan assumes a perfect crew every shift, it will fail. People get pulled into urgent jobs. Radios stay busy. The plan has to survive that messy reality.

How a Structured Servicing Plan Stabilizes Underground Haulage Systems

Good planning changes daily behavior. Trucks stop arriving at the bay only when something is already broken. Operators report early signs because they see follow-up, not blame. Maintenance becomes part of the production rhythm rather than a constant interruption.

You will see stability show up as fewer surprises in cycle time, fewer random stops on ramps, and less queue chaos at dump points. Blasting, ventilation shifts, and ground conditions still change the day. Your trucks become predictable anyway, and that predictability is gold underground.

It also helps your bottleneck work. When haulage is stable, it is easier to spot real constraints, like a narrow passing point or a dump interface that causes waiting. Without stability, everything looks like a “truck problem,” even when the root cause sits somewhere else.

How ZONGDA Approaches Servicing-Oriented Underground Equipment Design

When you source underground equipment, it helps to work with a manufacturer that treats servicing as part of system performance, not an afterthought. ZONGDA focuses on underground mining equipment where access, maintainability, and site realities matter. In practice, that points to design choices and support that fit underground work, where space is limited and service time is valuable.

For mines building a mining truck servicing plan, useful support tends to be practical rather than flashy: clear service access points, maintenance layout that makes sense in tight bays, and documentation that matches field behavior instead of ideal conditions. It also helps when a supplier can speak in system terms, because your target is not a truck that runs on its own. Your target is a haulage system that stays stable shift after shift.

Conclusion: Servicing Plans as Part of Underground Haulage Design

Servicing plan for mining trucks is a production tool. It is built from haul distance, ramp gradient, fleet utilization, temperature, and duty severity. It stays alive through cycle time signals, realistic service windows, parts planning, and access rules. It keeps reactive maintenance from becoming the default way of life.

If your underground mining trucks run hard, the plan must be simple enough to follow and sharp enough to catch problems early. Build it around how trucks actually work underground. Keep jobs small when possible. Stage parts. Protect service windows. That is how your underground haulage system stays steady, even when everything else changes.

FAQ

Q1: What is the real purpose of a servicing plan for mining trucks?

A: Your goal is predictable availability. The plan cuts surprise downtime, keeps cycle time steady, and avoids failures that jam traffic or stall loading.

Q2: How do you set service intervals when underground conditions change week to week?

A: Start with hours, then add duty signals. Watch brake heat on ramps, recurring temp alerts, coolant top-ups, and cycle time shifts that last several days. When those move, service priorities move.

Q3: Which systems most often cause long downtime for underground mining trucks?

A: Brakes on steep routes, cooling in hot headings, and hoses or fittings under heat and vibration. Dust and moisture also trigger stubborn electrical connector faults.

Q4: How do you stop servicing from getting skipped when utilization is high and bays are busy?

A: Plan around real windows and crew capacity. Use short checks at shift change, separate light vs heavy work, and avoid “quick fixes” that turn into hours underground.

Q5: How does a servicing plan connect to the underground haulage system, not just the truck?

A: Fleet stability drives queues, loader waiting, dump congestion, and cycle time. When truck uptime is predictable, bottlenecks show up faster and are easier to fix.