Understanding the Importance of Quality Spare Parts in Underground Mining

Spare Parts and Equipment Efficiency

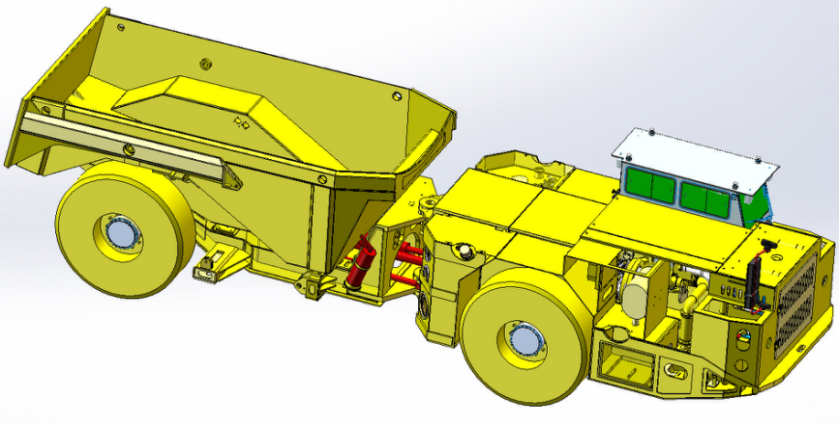

Underground mining utility vehicles are vital. They move people, tools, and materials in tough underground settings. Their performance hinges on spare parts. Quality parts keep vehicles running smoothly. They reduce downtime. They boost output. For example, hydraulic systems need to work flawlessly. Braking mechanisms must be reliable. Power transmission systems face heavy demands. The ZUPC-16 type Personnel Carrier has a sealed, air-conditioned cab. Its controls are centralized. This design eases operation. It adds comfort. High-quality parts make this possible. They ensure efficiency.

Safety and Productivity Benefits

Safety is critical in mining. The underground environment is risky. Quality spare parts lower failure risks. They protect workers. For instance, the ZUSL-3X Underground Scissor Lift Utility Vehicle uses a wet multi-disc hydraulic brake system. It includes MICO filling valves. This ensures safe operation. Reliable parts also cut breakdowns. They keep schedules on track. Certified parts add safety. FOPS and ROPS standards protect operators. These features boost productivity. They create a secure workplace.

Key Factors to Consider When Selecting Spare Parts for Underground Mining Utility Vehicles

Compatibility with Equipment

Parts must match specific vehicle models. Each model has unique specs. The right components ensure smooth function. For example, the ZDRU-8k Underground Personnel Carrier uses Cummins engines. It has Dana drive axles. These fit its design. Wrong parts cause problems. They reduce efficiency. They may harm equipment. Always check compatibility.

Durability and Material Quality

Parts must be tough. Underground conditions are harsh. High pressure is common. Moisture is a challenge. Abrasive materials wear parts down. Durable components last longer. High-strength structural steel is often used. Advanced welding adds strength. The ZUPC-16 Personnel Carrier uses steel stamping. Its parts handle heavy loads. They pass strength tests. This ensures long-term use. Quality materials matter.

Manufacturer Reputation

Choose trusted manufacturers. Their expertise ensures reliability. Look for certifications. ISO standards show quality. National safety marks add trust. QINGDAO ZONGDA MACHINERY CO., LTD offers custom solutions. Their experience in mining fields is deep. Reputable makers deliver safe parts. They meet industry needs.

The Significance of Genuine vs. Aftermarket Spare Parts

Benefits of Genuine Parts

Genuine parts are made for specific models. They fit perfectly. They perform at their best. Manufacturers often include warranties. This guarantees quality. Genuine parts pass strict tests. They meet industry rules. They’re reliable in tough mining tasks. Owners gain peace of mind.

Risks of Aftermarket Parts

Aftermarket parts may cost less. But they lack precision. They might not meet safety standards. Durability can be poor. This leads to frequent replacements. Equipment damage is a risk. Mechanical failures increase. These can harm operators. Long-term costs rise. Quality matters more than initial savings.

Tips for Identifying Reliable Suppliers for Mining Equipment Spare Parts

Researching Suppliers

Check a supplier’s history. Experience matters. A strong track record shows reliability. Suppliers should know mining needs. QINGDAO ZONGDA MACHINERY CO., LTD started 10 years ago. Its founders had deep mining expertise. They grew with global mining trends. This shows their skill. Look for years in business. It proves they meet changing standards. Reliable suppliers deliver quality parts. They understand underground challenges.

Product Support and Warranties

Good suppliers offer support. They provide technical help. They guide maintenance. Warranties show confidence in quality. The ZUPC-16 type Personnel Carrier uses advanced tech. It meets safety standards. Its structure is robust. Suppliers should back such features. They must offer after-sales care. This ensures customer trust. It helps solve issues fast.

Maintenance Best Practices to Extend the Lifespan of Underground Mining Utility Vehicles

Regular Inspections

Routine checks keep vehicles efficient. They catch wear early. This prevents failures. Inspect key parts often. Hydraulic systems need attention. Brakes are critical. Power transmission systems matter. The ZUSL-3X Underground Scissor Lift Utility Vehicle has a hydraulic brake system. Its MICO valves ensure safety. Replace worn parts quickly. This boosts reliability. It extends vehicle life.

Follow manufacturer schedules. Lubricate moving parts. Check fluid levels. Inspect structural strength. The ZUPC-16 Personnel Carrier uses strong steel. Its parts endure heavy loads. Regular care keeps it in top shape. It handles tough conditions well.

Trusted Service Providers

Work with skilled maintenance experts. They know mining equipment. They inspect thoroughly. They diagnose issues well. They suggest smart fixes. Preventive care stops big problems. It saves money. The ZDRU-8k Underground Personnel Carrier has Cummins engines. Its Dana axles are specific. Experts must know these models. They ensure precise care. This aligns with manufacturer specs. It keeps vehicles running longer.

Frequently Asked Questions

What should I check in a supplier?

Look at their experience. Check certifications like ISO or FOPS/ROPS. Review support services.

How often should vehicles be maintained?

Follow manufacturer guidelines. Inspect based on use. This keeps them safe and efficient.

Why is preventive maintenance key?

It spots issues early. It cuts downtime. It extends equipment life.

Are genuine parts better?

Yes, they fit perfectly. They’re durable. They ensure reliability for specific models.

How do I confirm part compatibility?

Check vehicle specs. Work with trusted suppliers. They verify fit before purchase.

Contact QINGDAO ZONGDA MACHINERY CO., LTD for custom solutions. Their expertise in underground mining utility vehicles ensures quality!