In underground mining operations, people blame trucks when haulage slips. The queue grows, cycle time stretches, and somebody says, “We need more fleet.” Sometimes that is true. Often it is not. The real trigger starts earlier, right at the face.

An underground drilling rig sets the tempo of material flow. It shapes how often you blast, how consistent fragmentation looks, and how smooth loading feels. Those upstream swings travel downstream fast, and the underground haulage system absorbs the shock. If you want stable haulage, you cannot treat face drilling as a separate world.

Why Drilling Rig Performance Matters Beyond the Face

Drilling is not only about getting holes in rock. What matters is how predictable the output is across shifts, headings, and weeks. Predictable drilling gives you predictable muck, predictable loading, and fewer surprises in dispatch. Unpredictable drilling forces everyone else to “make it work,” and that is where hidden losses pile up.

This is where the mining system view pays off. A drill rig underground can be running “fine” by its own metrics while the rest of the mine struggles. If the face delivers uneven blast results, trucks and loaders spend their time dealing with the aftermath. Nobody likes that kind of day.

Advance Rate as a System Input, Not a Drilling Metric

Advance rate gets treated like a drilling KPI, but it behaves like a system input. It controls how frequently the mine gets hit with new muck, how often loading ramps up, and how much dispatch pressure shows up right after blasting. When advance rate swings, the rest of the chain swings with it.

A practical way to think about it: production rhythm depends on how steady the drilling and blasting cycle stays. Mining drilling machine that produces highly variable progress will create peaks and gaps in material flow. Those peaks and gaps are what drive queues, idle time, and rushed decisions later.

Advance Rate Variability and Production Rhythm

When advance rate fluctuates, the mine sees pulses. One week you have faces advancing quickly, blasts landing on time, and plenty of muck. Then the next week delays stack up and the flow drops. Trucks do not “adapt” to that smoothly. Dispatch starts chasing moving targets.

You can spot this in simple signals: loader idle time rises after a dry period, then truck queuing spikes after a catch-up blast. That swing shows up as cycle time variability, even if trucks and operators did nothing different. It is frustrating, because it looks like a haulage problem while the root cause sits upstream.

When Advance Rate Outpaces Haulage Capacity

Sometimes the issue is not low advance rate. It is high output hitting a system that cannot clear it. A drilling mining machine can deliver blast-ready faces faster than the haulage loop can empty muck. Then the bottleneck shifts to loading bays, passing points, or dump interfaces.

In those cases, “more trucks” can even make things worse. More units mean more congestion in tight drifts, more passing delays, and more stop-start driving. The mine ends up with lots of steel moving slowly. It happens. People do not like admitting it, but it happens.

Drilling Accuracy, Blast Quality, and Truck Loading Efficiency

Hole placement and pattern consistency are not academic details. They decide fragmentation consistency. Fragmentation consistency decides how well a bucket fills, how often oversize shows up, and how much time gets lost to secondary breaking. That is where loading time quietly stretches, truck by truck, shift by shift.

This is why an underground mining drill matters even if it never leaves the face. A solid drill pattern helps you get blast holes that behave as expected. Less rework at the face means less chaos downstream. It sounds like common sense. Still, it gets ignored when everyone is rushing.

Fragmentation Consistency and Bucket Fill Factor

Consistent fragmentation improves bucket fill factor. When muck size distribution stays in a tighter range, loaders can keep a steady cycle. That directly stabilizes truck loading time, which is the first step in the haulage cycle.

This is also where terminology gets messy. Sites may call the unit a drill jumbo, talk about drill jumbos in general, or refer to an underground mining jumbo at the face. The name is not the point. The downstream effect is the point: consistent drilling and blast quality gives you more predictable loading.

Oversize, Secondary Breaking, and Queue Formation

Oversize changes everything. It slows the loader, blocks buckets, and forces secondary breaking. Secondary breaking takes time and space, both limited underground. While that happens, trucks queue. Drivers idle, engines run hot in place, and the ramp starts to feel smaller than it is.

The tricky part is that oversize does not hurt only one cycle. It creates a ripple. One slow loading event stacks trucks, then the dump point gets hit in a burst, then someone reroutes traffic. That is how a face issue becomes a haulage headache.

How Drilling-Driven Variability Turns Into Haulage Bottlenecks

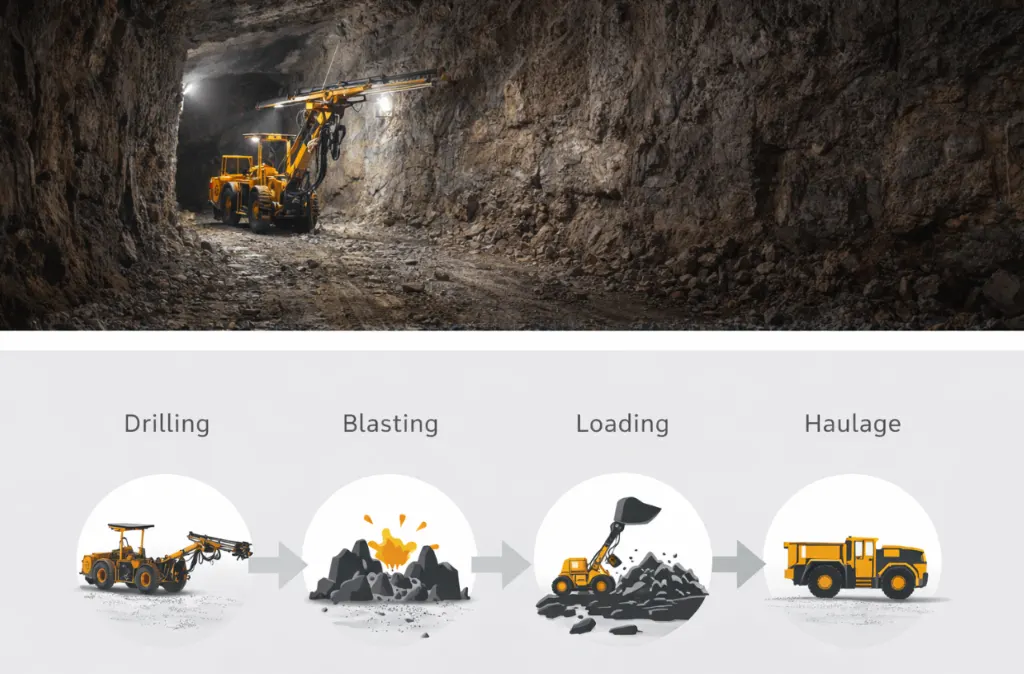

Drilling sets off a chain: drilling, blasting, loading, hauling, dumping, returning. Variability anywhere in the front half usually shows up as instability in the back half. When that variability repeats, it turns into a bottleneck pattern that feels permanent.

This is the spot where system mining thinking prevents bad fixes. If the mine treats symptoms only, the common move is to add trucks, add shifts, or push operators harder. Those moves can raise output for a short time. They can also raise congestion, tire wear, brake heat, and unplanned downtime. The mine pays for it later, usually on a week nobody can afford to lose.

Why Haulage Planning Must Consider Drilling Rig Behavior

Haulage planning often starts with truck payload, route length, and fleet size. That is fine, but it is incomplete if drilling behavior is ignored. A drill rig machine underground drives the shape of material flow. Planning that does not include that reality ends up chasing yesterday’s problem.

Two simple questions help: Is the face producing consistent muck, and is the release timing predictable? If the answer is “not really,” then haulage planning should include buffers, traffic rules, and dispatch logic that can absorb pulses. If the answer is “yes, mostly,” then the mine can tighten dispatch and push for smoother cycle times.

This is also where maintenance planning ties in. If blasting and loading arrive in bursts, trucks see more stop-start work and more idling in queues. That changes wear patterns. Your servicing plan should reflect that, even if the truck schedule looked perfect last month.

How ZONGDA Approaches Drilling Equipment from a System Perspective

Underground mining machines do not operate in isolation, even when procurement treats them that way. Equipment selection and support work better when they match how the mine actually runs: tight headings, shifting ventilation conditions, variable ground, and short service windows.

ZONGDA’s underground machines portfolio sits in that system view. When you evaluate underground drilling equipment, the practical questions usually matter more than glossy claims: service access at the face, predictable operation across long shifts, and support that fits remote sites where parts and time are both limited. That system-first mindset also makes it easier to align drilling output with downstream loading and haulage targets, instead of pushing one area so hard that another area breaks.

Conclusion: Stable Drilling Sets the Upper Limit for Haulage Efficiency

Haulage efficiency is not decided only by trucks. The upstream rhythm matters. An underground drilling rig influences advance rate, blast quality, fragmentation consistency, and the timing of material release. Those factors decide how smooth loading runs, how often queues form, and how stable cycle time looks across the underground haulage system.

If haulage feels unstable, look upstream before you buy more fleet. Check drilling consistency, blast outcomes, and oversize patterns. Then plan haulage around the real flow, not the flow you wish you had. That approach is less dramatic. It also works more often.

FAQ

Q1: What keywords matter most for this topic if you are writing about drilling and haulage together?

A: Focus on underground drilling rig, drill rig underground, underground drill rig, and underground mining operations, then support with drilling and blasting cycle and underground haulage system where they fit naturally.

Q2: How does drilling performance show up in truck cycle time without changing the truck itself?

A: Variable fragmentation and release timing change loading time and queuing. That stretches cycle time even when trucks, routes, and drivers stay the same.

Q3: Where does “drill blast” fit in a system-level explanation?

A: Use it when discussing blast holes, timing, and fragmentation outcomes. Keep it tied to downstream effects like loading efficiency and bottleneck formation.

Q4: Should you mention drill jumbos and underground mining jumbo in the same article?

A: Yes, but only as natural industry terms. One or two mentions are enough, and they should sit in the fragmentation and loading section, not in the title.

Q5: What is one planning mistake that causes repeated haulage bottlenecks underground?

A: Planning trucks in isolation while ignoring drilling-driven variability. Pulses from the face create queues and congestion that no simple fleet increase can fix.