Subsurface mining is a complex and advanced undertaking that requires efficient and reliable machinery to enable easy operations. Underground dump mining trucks in underground mining are among the fundamental equipment used in such an undertaking, and they are engineered to form a fundamental part of road construction.

These dump Underground dump mining trucks are made to operate in the tough underground mine conditions, where space is limited and safety is entirely essential. Their impact on underground road development is tremendous, as they are used in the majority of the mining operation areas, from the transportation of material to increasing defense.

Major Role of Underground Mining Dump Trucks in Roadway Development

Successful Transport of Materials

Underground dump trucks play a significant role in the transportation of material in an efficient way in the mine. They are intended for hauling enormous loads, minimizing trips, and thus providing maximum overall productivity. Such efficiency is needed most in underground conditions, where time is limited and space is restricted.

Reducing Roadway Construction Time

Application of dump trucks in trackless underground mining significantly reduces roadway construction time. The trackless dump mining trucks can maneuver through confined spaces and challenging terrain with ease, hence enabling the construction of roadways required for mining at a rapid pace.

Optimizing Roadway Layout and Spacing

The small size of these trucks facilitates easier optimization of road spacing and arrangement. Through the use of Underground Articulated Dump Trucks, mines are able to optimize their space such that roadways are set in a way that ensures free flow of traffic without congestion.

Improved Safety

Safety is also an issue when it comes to the mining operation, and dump underground dump trucks in underground mining are responsible for delivering it. The overall hydraulic control system of trucks like the 70 Ton Underground Mining Dump Truck HOWO 6X4 Dumper Truck delivers safety, comfort, and ruggedness. Such features minimize accidents to the minimum and instill confidence among drivers.

Increased Productivity

By reducing material hauling and saving building time, these dump trucks optimize overall plant productivity within the mine. By transporting huge amounts of material at full capacity, mining operations are able to achieve production rates more effectively.

Cost Savings

The efficiency brought by Diesel Dump mining trucks in subterranean mining saves costs of gigantic magnitudes. Fewer trips for carrying material mean fewer fuel consumptions, which correspond to lower operation costs in the long term.

Types of Underground Mining Dump Trucks and Roadway Design Impacts

Rigid Dump Trucks

Rigid dump trucks are notable due to their high tolerance and rigid structure. They can be used in broad tunnels where there is plenty of space. Since they cannot bend, they are not best suited for use in curved and narrow roads.

Underground Articulated Dump Trucks

Articulated Dump Underground Mining trucks are more mobile for underground use than rigid ones. They are capable of turning comfortably through small corners and small spaces because of articulation, and that is the reason why numerous underground operations make use of them.

Electric Dump Trucks

Electric dump trucks are a growing trend towards cleaner operation for mining. They are less environmentally damaging than their diesel counterparts, and therefore provide a green alternative that is suitable for the current regulatory environment.

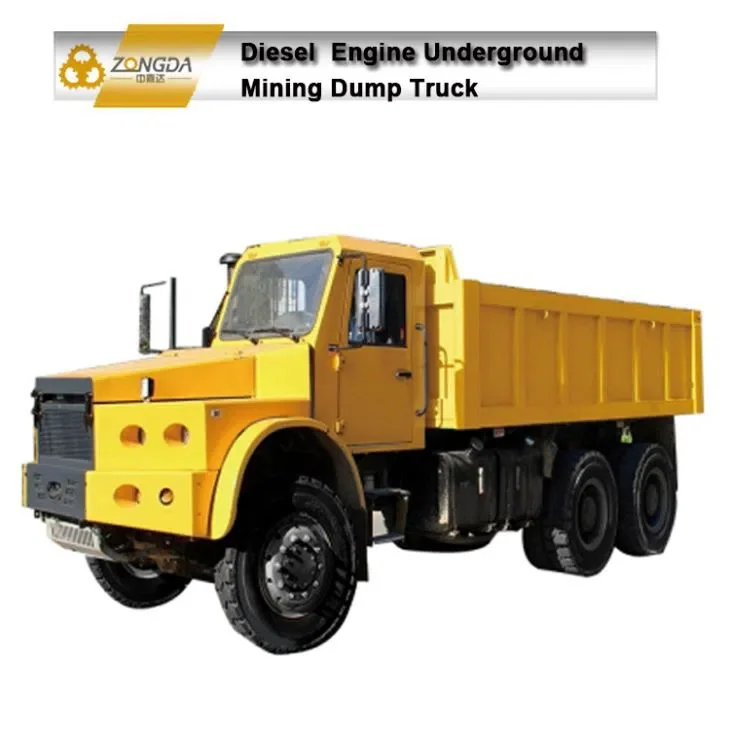

Diesel Engine Underground Mining Dump Trucks

Diesel engine trucks are favored as they are powerful and durable. The Diesel Chinese Engine Underground Mining Dump Truck is one of the products that reflect heavy-duty capability for harsh underground environments.

How Advanced Underground Mining Dump Trucks Upgrade Roadway Construction

Improved Design for Constricted Spaces

Sophisticated manufacture makes it possible for these trucks to work optimally in the constricted conditions common in subterranean mines. Central articulated hydraulic steering is one of the features that makes it possible for them to achieve high steering angles to provide precise control even in narrow corridors.

Safety Improvements

Safety improvements are always the priority when they engineer them. Improvements such as wet multi-disc hydraulic brakes supply greater stopping power under difficult conditions, overall safer mines.

Challenges & Solutions in Underground Haulage

Overcoming Ventilation Limitations with Low-Emission Engines

The condition of underground mining usually faces issues of ventilation due to confined places and diesel fumes. While attempting to neutralize this difficulty, the usage of low-emission engines in Diesel Dump Trucks during underground mining is essential.

These engines produce fewer toxic gases, and air quality is therefore enhanced, and therefore ventilation systems for mass operation are not needed. Adoption of this technology must be done to make working environments healthy and safe for underground working conditions.

Preventing Roadway Wear Through Smart Weight Distribution

Subways are prone to excessive wear and tear due to relentless movement of heavy-duty vehicles. Smart load distributing systems incorporated in existing trackless underground mining dump trucks minimize this to a great extent.

These minimize excessive stress to roadway surfaces by even loading among the vehicle. This enhances roadway life along with minimizing the cost of maintenance.

Balancing Payload Capacity with Tunnel Height Constraints

Among the top priorities in underground haulage is payload capacity versus tunnel height limitations. Underground Articulated Dump Trucks are specifically built to overcome such limitations decisively.

Their adaptability and slender width allow them to transport heavy loads as they navigate through tunnels with limited clearance without any compromise on safety or structural limitations.

Keeping Roadways Intact

Precise Measurements and Roadway Design

Truck design parameters become an important input in designing underground roadway configuration and size. Along with coordination with roadway design and truck capacity, traffic flow could be supplied by mining operations undisturbed and uncongested.

This not only is most effective in operation but also lowers the risk of accidents due to insufficient space or poorly planned routes.

Rapid Response to Roadway Condition Changes

Mining operations are not constant, but with continuous need to adapt to changing processes. or circumstances.

The ability of today’s mining trucks, such as those produced by Qingdao Zongda Machinery Co., Ltd., to make sudden adjustments to changed roadway alignments or changes in the operational requirements to allow uninterrupted operations even as circumstances are being changed.

Role of Mining Trucks in Roadway Preservation Over Time

Truck mines play crucial roles on roadways in the long run by avoiding unwanted traffic from using the roadways and not excessively wearing out the road surface. Through good design, effective haulage truck mines ensure reduced numbers of haulage trips are taken, and thus reduce road surface wear and maintenance.

Underground Mining Dump Truck Selection

The selection of the appropriate mining truck considers several parameters, such as load-carrying capacity, fuel efficiency, truck type (rigid or articulated), and road class. These factors ensure the chosen vehicle performs the intended application to the benefit of the operation with optimal performance and economic effectiveness.

Construction that can Last

Underground mines require rugged construction of mining dump trucks, as conditions are harsh. They must be built to work under extreme conditions, not just for their longevity but also for that of the roadways over which they travel. Heavy capitalization in heavy-duty machinery guarantees extended operation and reduces downtime for repair or replacement.

Qingdao Zongda Machinery Co., Ltd., its reputation for creating solutions to manufacturing high-quality underground dump trucks, is setting the pace in mining machine technology globally to address different business needs with precisely styled products whose principal concern is efficiency, security, and ecocompatibility.