How Does Size Influence Safety in Mining Equipment?

The Importance of Equipment Size in Underground Mining

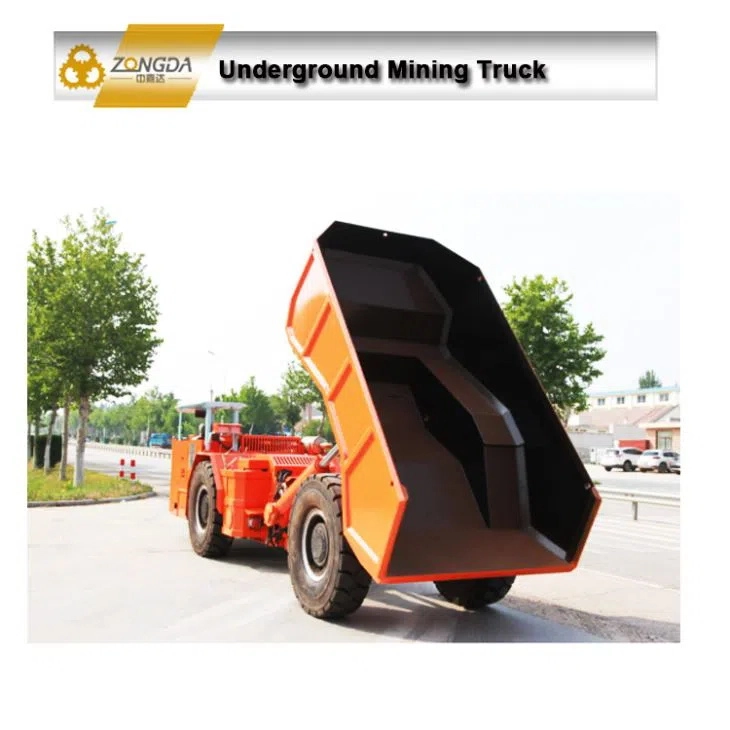

In the world of mining operations safety is heavily influenced by the equipment size used in these settings. Machinery can handle heavier loads and enhance overall efficiency levels considerably. Nevertheless, these machines must be specifically crafted to maneuver through the spaces commonly found in mines without compromising on safety standards. Maintaining an equilibrium, between size and operational effectiveness becomes paramount to upholding operations while also safeguarding personnel from potential risks.

Challenges Faced by Large Machinery in Confined Spaces

Using the mining machinery in confined spaces poses distinct difficulties. These vehicles need to navigate tunnels and sharp bends with their size posing a challenge. Moreover, it is vital to ensure visibility and communication, among team members as the bulkier equipment can block lines of sight and cause spots. Overcoming these hurdles demands design resolutions and the incorporation of cutting-edge technology.

Balancing Size with Maneuverability and Safety

Maintaining a balance, between the size of mining equipment and its maneuverability is crucial to ensure operations on site. Engineers work on creating machines that can sustain their structure while also being able to move through spaces. By including technologies such, as articulated steering systems and compact designs they aim to improve maneuverability without compromising on efficiency or safety measures.

What Safety Standards Govern Underground Mining Equipment?

Overview of International Safety Regulations

In order to ensure the safety of workers and the environment, underground mining equipment must comply with safety guidelines set forth by organizations, like the International Standardization Organization (ISO). These regulations aim to reduce the dangers linked to using machinery in risky underground conditions.

Key Safety Features Required for Compliance

Meeting safety guidelines requires integrating elements into mining machinery like sturdy braking mechanisms, emergency shutdown capabilities, fire suppression systems, and protective cabins for operators. These components are essential to avoid mishaps and promptly deal with any dangers that may arise.

The Role of Regular Inspections and Maintenance

Regularly. Maintaining equipment is crucial for safety in mining operations. It’s important to conduct inspections to catch any signs of wear and tear early and prevent breakdowns. This does not extend the lifespan of the equipment. Also ensures that safety standards are consistently met.

How Do Modern Technologies Enhance Safety?

Integration of Automation and Remote Control Systems

The incorporation of automation and remote control systems, into equipment design has significantly transformed safety measures in mining operations at times.

Benefits of Automation in Hazardous Environments

Automation decreases contact, with situations by enabling machines to independently carry out tasks or be monitored remotely thereby lowering the likelihood of mishaps resulting from human mistakes or environmental dangers.

Remote Monitoring for Enhanced Operator Safety

Remote control systems empower operators to oversee machinery from a distance to minimize their exposure, to environments effectively. This innovation bolsters safety by enabling monitoring and regulation of mining operations, in real time.

Advanced Sensor Technologies for Risk Mitigation

Cutting-edge sensors are crucial, in reducing risks by offering up-to-date information, on how equipment functions and the surrounding environment.

Real-time Monitoring Systems

Monitoring systems, in real-time rely on sensors to monitor factors like temperature and gas levels, in mines to detect irregularities promptly and take action before they develop into problems.

Predictive Maintenance to Prevent Failures

Anticipatory maintenance utilizes sensor information to predict equipment malfunctions over time to prevent them from happening unexpectedly or causing downtime by fixing issues in advance through trend and pattern analysis, by maintenance teams.

Why is Operator Training Crucial for Safe Operations?

Comprehensive Training Programs for Equipment Operators

It’s essential to provide training to operators for ensuring mining operations since it gives them the skills needed to effectively operate complex machinery, on-site and handle emergencies following proper safety protocols.

Simulation-Based Training for Realistic Experience

Operators benefit from simulation-based training as it offers practice opportunities without subjecting them to real-life dangers or risks. They can enhance their skills by simulating scenarios and gaining confidence, in dealing with emergencies or difficult situations.

Continuous Skill Development and Certification

Operators in mining operations stay current with technologies and methods, through skill enhancement efforts to uphold safety standards and best practices as verified by routine certification programs.

To learn more, about the advancements in designing mining equipment that puts safety first without sacrificing productivity effectiveness in conditions be sure to check out QINGDAO ZONGDA MACHINERY CO., LTD.s offerings. Their groundbreaking solutions demonstrate a dedication, to pushing industry norms while delivering top-notch performance in settings.

What Role Does QINGDAO ZONGDA MACHINERY CO., LTD Play in Ensuring Safety?

Overview of QINGDAO ZONGDA MACHINERY CO., LTD’s Commitment to Safety

QINGDAO ZONGDA MACHINERY CO., LTD is known for its dedication to innovation and safety within the mining sector. Their strong emphasis on safety is demonstrated by their adherence to safety standards and ongoing investment in research and development. By focusing on producing equipment that not only meets but surpasses safety requirements they guarantee that mining activities are carried out with risks to both workers and the environment. The company offers a range of products with safety features ensuring that each machine functions reliably even in challenging environments.

Innovative Solutions Provided by QINGDAO ZONGDA MACHINERY CO., LTD

Customization Options for Specific Mining Needs

At QINGDAO ZONGDA MACHINERY CO., LTD. they provide customized solutions to address the needs of mining settings by working closely with customers to tailor equipment specifications, for improved efficiency and safety measures tailored to each machine’s specific operational requirements.

Cutting-edge Technology Integration in Their Products

QINGDAO ZONGDA MACHINARY CO., LTD stands out for incorporating state-of-the-art technology into its products ranging from automation to remote control systems to enhance efficiency and uphold safety protocols effectively reducing accident risks while boosting productivity significantly.

How Can You Ensure Effective Implementation of Safety Measures?

Developing a Culture of Safety Within Mining Operations

Establishing a work environment that places an emphasis not only on following rules but also on encouraging all team members to appreciate and engage in safe practices is essential, for prioritizing safety culture development. Encouraging discussions, about risks and supporting ongoing education play crucial roles in shaping this kind of culture.

Collaboration Between Manufacturers and Mining Companies

Collaboration between equipment manufacturers such as QINGDAO ZONGDA MACHINERY CO., LTD, and mining companies is key to implementing safety measures in the workplace.

Regular Review and Update of Safety Protocols

Consistently checking and revisiting safety procedures guarantees they stay up-to-date and are capable of dealing with changing dangers. The stance assists, in pinpointing new risks adapting plans as needed, and keeping a secure workplace for everyone working in mining activities.

What Are the Future Trends in Safe Mining Equipment Design?

Emerging Technologies Shaping the Future of Mining Safety

AI and Machine Learning Applications

AI and Machine Learning are transforming the design of mining equipment by using analytics to schedule maintenance and improve machine performance while also enhancing decision-making processes. These advanced technologies offer real-time insights that play a role, in preventing accidents.

Sustainable Practices in Equipment Design

The importance of sustainability, in the design of mining equipment, is on the rise with a focus on using eco materials and energy technologies to minimize environmental harm without compromising safety standards aligning with the industry’s move towards reducing ecological footprints.

Anticipating Changes in Regulatory Standards

As the regulations keep changing over time and becoming more advanced, in nature; it is essential to stay informed and adjust designs proactively to meet these evolving standards as they arise. A company such as QINGDAO ZONGDA MACHINARY CO., LTD is leading the way by introducing ideas to make sure their products not only meet present regulatory demands but also anticipate future needs.

By utilizing cutting-edge technologies and building partnerships while prioritizing safety measures at all times QINGDAO ZONGDA MACHINERY CO., LTD showcases the balance, between productivity and protection in contemporary mining endeavors. To learn more, about their solutions designed specifically for underground activities, you can visit the QINGDAO ZONGDA MACHINERY CO., LTD website.