1. Emergences of Lithium Battery-Powered Mining Locomotive

The global mining fraternity is in a state of flux, with increasing emphasis on sustainability and operational efficiency. This transformation is taking place, among other arenas, with the adoption of electric vehicles, more so lithium battery-powered mining locomotives. Such locomotives replace diesel-powered units on account of their superior performance, low emissions, and reduced operating costs.

That means China, being the big player both in mining and in battery technology, has taken the lead in the shift whereby several companies produce advanced lithium battery-powered mining locomotives to meet increasing demand. This move towards battery-powered locomotives is strategic, going beyond environmental concerns, in ways that boost productivity and safety inside mining operations.

2. Major Benefits of Lithium Battery-Powered Mining Locomotives

The following are some advantages of lithium battery-powered mining locomotives over diesel ones. They will contribute toward efficiency, safety, and a friendly mining environment.

2.1 Improved Operational Efficiency

However, the mining locomotives powered by a lithium battery are operationally way more efficient compared to conventional locomotives. They have a high energy density, which is translated to more power in a package that is both smaller and lighter. They will be able to sustain even the heaviest loads for longer distances without requiring to recharge as frequently.

In addition to this, lithium-ion batteries can be recharged fairly quickly to reduce any amount of downtown time and increasing overall productivity.

For example, some lithium batteries are fully charged in two to three hours while it takes eight or more hours for lead-acid batteries. Furthermore, lithium batteries maintain higher motor speeds because of the consistent voltage discharge thus giving the illusion of more power while finishing the work quicker. 2.2. Improved Safety Standards

Safety is of utmost importance in underground mining. Simultaneously, lithium battery-powered mining locomotives enhance these safety features even further. Besides having zero emission, unlike those from diesel engines, they have no harmful gases, which essentially decreases demands on ventilation and creates a far healthier working atmosphere for miners. Furthermore, modern lithium batteries come with sophisticated battery management systems (BMS) that monitor voltage, current, and temperature, preventing issues like overcharging, overheating, and short circuits.

2.3. Reduced Environmental Impact

This makes the mining locomotive, powered by lithium batteries, reduce the environmental footprint caused by mining activities. They do not emit any kind of emission which adds to the greenhouse gases; neither do they support the continuance of keeping the environment clean for sustainability. Further, lithium batteries save hazardous handling and waste disposal activities relating to lead-acid batteries. The longer life of lithium batteries reduces further waste generation.

Some manufacturers are also studying how lithium batteries from locomotives can be reused in residential or commercial settings once their lifecycle for mining operations is complete, further extending their sustainability. Research by the International Council on Mining and Metals puts the estimated reduction in greenhouse gas emissions that can be achieved by adopting electric vehicles in mining operations at up to 30% by 2030.

3. Front Running Chinese Suppliers of the Lithium Battery-Powered Mining Locomotives

Only a few companies have so far taken the lead in the design and manufacture of lithium battery-powered mining locomotives in China. The suppliers provide a range of products, all with specifications, as outlined herein, targeted at meeting varied demands from various mines.

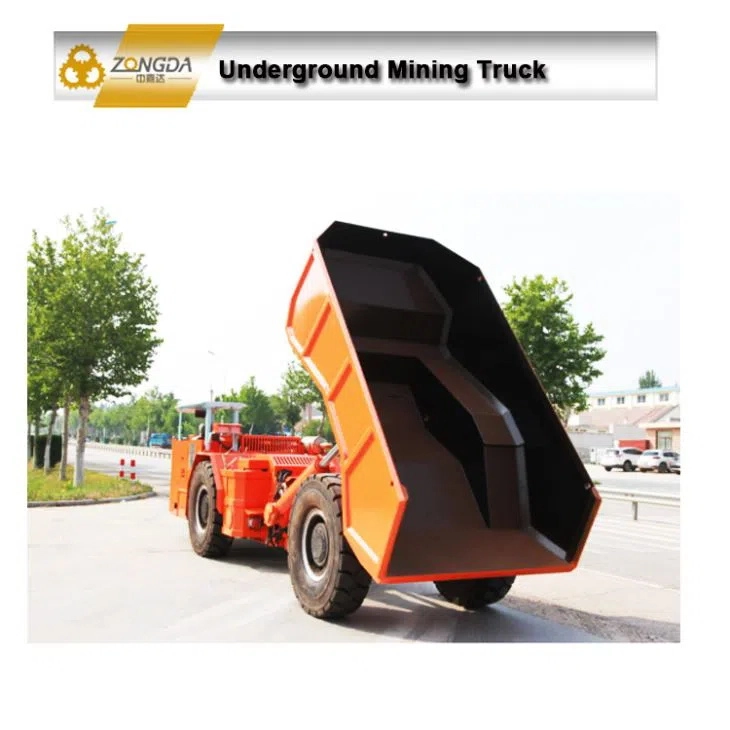

3.1. ZONGDA Machinery

QINGDAO ZONGDA MACHINERY CO., LTD was a professional manufacturer with ten years of experience in exploration and mining machinery. It has grown to be one of the largest suppliers of mining equipment in China. ZONGDA will keep on researching and developing to give its customers cost-effective solutions. The company offers a range of lithium battery-powered mining locomotives designed to meet the most rigorous demands in underground mining. Comfort and safety are amongst the top points in their list of design aspects, together with durability. It comes with guaranteed long service life, fast recharge, and fewer maintenance liabilities in its advanced lithium battery systems.

Locos manufactured by ZONGDA use a similar BMS in an automobile to keep safety and reliable performance. On-site installation and commissioning are assured, together with post-sales technical service. Besides the lithium battery-powered mining locomotive, ZONGDA has a lot of trackless mining equipment, including underground mining trucks, underground loaders, and underground ventilation systems.

4. Technical Parameters and Development in Lithium Battery-Powered Mining Locomotives

Technical specifications of a lithium battery-driven mining locomotive determine its efficiency and suitability to perform different operations in mines. The advancement of battery technology and design, alongside the safety dimension, is setting new standards and breaking new horizons for lithium battery-driven locomotives.

4.1. Battery Technology

The contribution of lithium-ion batteries in these locomotives results from their contribution of high energy density, rapid charging capability, and long life cycle. The batteries use either lithium cobalt oxide or lithium iron phosphate cathodes with graphite anodes in order to optimize energy storage and charging. As an example, lithium batteries have reached up to 150-200 Wh/kg today, far better compared with the 30-50 Wh/kg by lead-acid batteries. Besides, these batteries are designed with strength and performance for the worst of conditions. A lithium battery pack from Frey provides ≥3,000 times the cycle life at 80% depth of discharge. Moreover, there are some manufacturers that currently develop solid-state or ceramic batteries, which will boast even higher energy density, safety, and speed in charging.

4.2. Design and Performance

The design considerations for lithium battery-powered mining locomotives incorporate several features in the quest for optimal performance and durability. These locomotives are designed for heavy loads, as some of their models have been designed to haul up to 30 tons of ore in one run. They are also designed to operate efficiently in cramped spaces, with articulated frames that facilitate maneuverability.

Another novelty is that the design integrates the charger and battery pack, thereby removing the need for a separate charging bay. This reduces infrastructure costs and saves precious space within underground mines. The locomotive batteries will also be equipped with rugged casings to protect against mechanical damage.

4.3. Safety Features

Safety is one of the most critical design factors for mining locomotives powered by lithium batteries. Most of them have a BMS included that monitors key parameters to prevent hazards such as thermal runaway. The battery packs are also explosion-proof for added safety underground.

Besides, lithium batteries avoid the release of toxic gases and fumes into the air of mines. Among the features, one may point out the casings, which will protect the battery from physical impact.

5. Things to Keep in Mind When Selecting a Lithium Battery-Powered Mining Locomotive

Supplier

Selection of any lithium battery-powered mining locomotive supplier has to take a lot of factors into consideration. Some of these factors are the extent of customization a supplier can extend, post-sales support, and their adherence to industrial standards.

5.1 Customization and Flexibility

Mining operations may be highly variant of their own kind. It will, therefore, be very good to select a supplier who can provide customized solutions based on the particular needs a certain operation will have. This may include anything from locomotive size up to battery capacity and charging systems. Suppliers such as Frey New Energy will be supplying customized lithium battery packs for a range of mining applications. In a similar vein, ZONGDA focuses on specific customer requirements through cooperation and innovation. Ability to adapt into specific operational requirements shows the mark of a reliable supplier.

5.2. After-Sales Support and Maintenance

The aftersales support and maintenance for lithium battery mining locomotives are necessary to ensure a long-lasting performance and reliability. Good suppliers would offer installation, commissioning, on-site technical support service, and a timely supply of spare parts. In this case, they could respond very quickly to any issues, with less time wasted in making the locomotive out of operation. Some suppliers provide remote monitoring of battery performance for proactive maintenance and issue resolution.

6. Prospect for Lithium Battery-Powered Mining Locomotive in China and Abroad

In the light of continuously changing technology, the lithium battery-powered mining locomotive will become a vital element of the mining industries of the whole world.ZONGDA Machinery is committed to offering innovative, reliable lithium battery-powered mining locomotives to meet the new challenges of the global mining industry.

With ten years of experience and insistence on continuous research and development, ZONGDA provides robust solutions for safety, efficiency, and environmental responsibility. The mining locomotives manufactured by the company are powered with lithium batteries equipped with advanced battery systems, which guarantee long life and minimal maintenance. The locomotives further offer fast charging and have integrated charging systems that dispense with the need to use a charging bay, saving considerable time and reducing set-up costs. Contact ZONGDA Machinery today for your Lithium Battery-Powered Mining Locomotive need