The Workhorse of the 4.5m Heading

In the demanding world of underground hard rock mining, the 14-tonne loader is the undisputed king of production. Sized perfectly for standard 4.5m x 4.5m headings, these machines are massive enough to fill a truck in three passes but compact enough to navigate the decline without bottlenecking traffic.

For years, the market has been dominated by a few premium names, with the Sandvik LH514 often cited as the benchmark. However, as operating costs rise and lead times stretch, savvy procurement managers are looking closer at the spec sheets. The question is no longer just “which brand is famous,” but “what is actually under the hood?” When evaluating LH514-class loaders, look past the logo and analyze the core components—the engine, the transmission, and the control logic—to figure out where your money is really going.

The “Shared DNA”: Global Tier-1 Components

The most surprising realization for many buyers is that the “guts” of a cost-effective challenger often match the premium incumbent part-for-part. A high-quality 14-ton underground loader is essentially an integration of global Tier-1 components, packaged in a heavy-duty chassis.

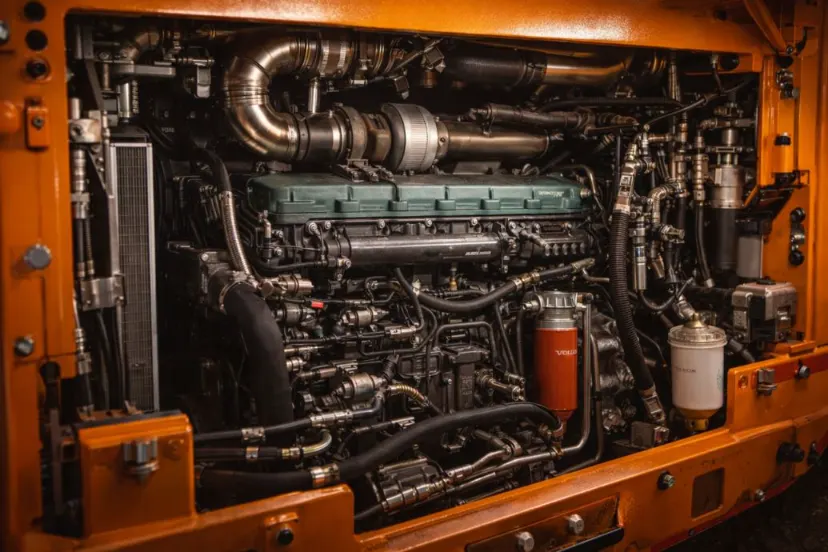

The Powerhouse: Volvo TAD 1350 VE

At the 14-ton level, air-cooled engines are no longer viable due to the sheer power density required to move that much rock up a ramp. You need a liquid-cooled beast.

The ZONGDA ZDL614 utilizes the Volvo TAD 1350 VE. This is a massive 13-liter, inline 6-cylinder diesel engine pumping out 256 kW at 1900 rpm. It is the exact same power plant found in many top-tier Western machines. It offers high torque (2175 N·m) for steep ramp hauls and meets the strict emission standards required in modern underground hard rock mining environments.

The Drivetrain: Dana and Kessler

The power is useless if it cannot get to the wheels. This is where the ZDL614 underground mining loader matches the industry standard blow-for-blow.

- Transmission: It uses the DANA 6422 power shift transmission paired with a C8602 torque converter. This is an electronically controlled, four-speed unit known for smooth shifting under heavy loads.

- Axles: The machine sits on Kessler D106 (or optional Dana 53R) axles. These German-engineered axles are equipped with wet multi-disc brakes and anti-slip differentials, designed specifically to handle the abuse of abrasive mine floors.

So, if the engine, transmission, and axles are identical to those found in machines costing twice as much, where is the difference?

The Control System Debate: Electronics vs. Hydraulics

The divergence between a “Smart Mine” loader and a “Production” loader usually lies in the control system. This is a critical decision point for your maintenance team and dictates how often the machine stays in the workshop versus at the face.

The Cost of Complexity

Premium LH514-class machines are often heavily digitized. They feature complex Vehicle Control Modules (VCM), dozens of sensors, and proprietary software designed for automation readiness. While impressive, this complexity can be a liability. A single sensor fault can put the machine into “limp mode,” requiring a specialized technician with a diagnostic laptop to reset it. If you are in a remote site, waiting for that technician kills your production targets.

The Reliability of Pilot Controls

In contrast, the ZDL614 underground loader favors a pilot-operated hydraulic design. The bucket and boom are controlled by electric joysticks driving a piston pump, but the logic remains fundamentally hydraulic.

- Easier Troubleshooting: If a function fails, your local mechanic can usually trace the hydraulic pressure or check a solenoid valve.

- Higher Uptime: There are fewer “black box” electronic ghosts to stop the machine. For mines in remote locations without a resident software engineer, this simplicity translates to higher availability.

Spec-by-Spec Comparison: The Numbers

To make an informed choice, it helps to see the raw data side-by-side. The following table highlights the capabilities of the ZDL614 in the context of the 14-ton class.

| Feature | ZONGDA ZDL614 | LH514 Class Standard |

|---|---|---|

| Tramming Capacity | 14,000 kg | 14,000 kg |

| Standard Bucket | 6.0 m³ | 5.4 – 6.0 m³ |

| Engine | Volvo TAD 1350 VE (256 kW) | Volvo TAD13 Series |

| Transmission | DANA 6422 + C8602 | Dana 6000 Series |

| Axles | Kessler D106 / Dana 53R | Kessler / Dana |

| Breakout Force | 225 kN (Lift & Tilt) | ~200 – 230 kN |

| Control System | Pilot Operated (Hydraulic) | Electronic (VCM) |

Maintenance and Operator Comfort

A loader is only as productive as its operator. If the cab is uncomfortable or unsafe, cycle times drop, and fatigue sets in. This is true for any underground hard rock mining operation where shifts are long and conditions are tough.

Ergonomics and Safety

The ZDL614 does not cut corners on the human element. It features a fully enclosed cab with heating and cooling air conditioning—a mandatory requirement for the heat generated by a 13-liter engine.

- Space: The legroom is generous, and the layout provides excellent visibility over the low-profile rear frame.

- Protection: The cab is ROPS/FOPS certified. The operator sits safely within the frame, protected from hazardous areas.

Serviceability

The central articulation uses an adjustable bearing connection, and the rear axle employs a double-support swing frame to reduce stress failures. Crucially, all maintenance points (filters, fill ports) are well protected behind heavy steel guarding yet remain accessible for the daily service round.

Conclusion: Making the Right Choice

When choosing an LH514-class loader, the decision comes down to your operational philosophy.

If your mine is moving toward full automation and you have a high-tech support infrastructure, the premium electronic features of the big brands are valuable. However, if your priority is moving tons of rock reliably, and you want the brute force of a Volvo engine and Dana transmission without the electronic complexity (or the price tag), the ZONGDA ZDL614 is the pragmatic choice. It delivers the same 14-ton payload with a mechanical simplicity that keeps your maintenance team happy.

Meet ZONGDA: The Specialist in Underground Metal Mining

Qingdao ZONGDA Machinery Co., Ltd. is a focused maker filling the spot between high-price West build and the want for cheap mine fixes. Unlike broad sellers that might push all from diggers to lift trucks, ZONGDA sticks only to underground metal mining—mainly for Gold, Copper, Iron, and Lead-Zinc jobs. They skip gear for coal spots.

Set in Qingdao, the group focuses on low-shape fixes, giving a group that holds Underground Mining Trucks from 8 to 35 tons and LHD Loaders from 0.6 m³ to 6 m³. Their build way is “Easy & Strong.” By mixing world-top bits—like Volvo engines, Deutz engines, and DANA powertrains—into tough, simple base plans, ZONGDA hands a real group choice. This path lets mines in far spots balance start cash saves with the run ready needed in rough hard-rock spots. Whether you want a small 0.6 cbm scooptram for thin lines or a 14-ton output loader, ZONGDA brings trusty iron without the extra electric bits.

FAQ

Q1: Does the ZDL614 use the exact same engine as the Sandvik LH514?

A: Both machines typically use the Volvo TAD13 series engine. The ZDL614 specifically uses the Volvo TAD 1350 VE, a 13-liter water-cooled engine famous for its reliability and global parts availability.

Q2: Can I get spare parts for the ZDL614 locally?

A: Yes, for the critical powertrain components. Since the engine is Volvo and the transmission is Dana, you can source filters, seals, and internal parts from your local Volvo or Dana distributors.

Q3: Is the ZDL614 suitable for automation or remote control?

A: The standard ZDL614 is designed for manual pilot operation, focusing on mechanical reliability. However, line-of-sight remote control interfaces can be installed upon request.

Q4: What size tunnel is this machine designed for?

A: It is optimized for 4.5m x 4.5m headings. It can operate in slightly smaller tunnels, but you need to check the corner radius and ventilation capacity carefully.

Q5: How does the pilot control system differ from electronic control?

A: Pilot control uses hydraulic pressure to actuate the main valves. It provides excellent “feel” for the operator and is much easier to repair than electronic “fly-by-wire” systems that rely on computer codes and sensors.