The Role of Mining Equipment Manufacturers in Ensuring Safety

Importance of Safety in Mining Equipment Design

Mining equipment manufacturers hold a key position in safeguarding mining operations. The creation and refinement of mining equipment are vital. They directly affect the well-being of workers in dangerous settings. “Our Flame Proof Mining Battery Locomotive, underground concrete transmixer, Underground Electric Loader draws in and unites more top-tier clients, skilled workers, and reliable suppliers to achieve excellence.” This shows the emphasis on building dependable and secure equipment that aligns with industry benchmarks.

Advancements in Equipment Technology for Safety

Progress in technology has greatly improved the protective aspects of mining equipment. Adding modern tools enhances oversight and management. This lowers the chance of mishaps. “The driving and control system uses a sensible ergonomic arrangement, a sealed air-conditioned cab, and a unified control setup, making it simple to use and pleasant.” These improvements allow operators to perform tasks effectively while cutting down on dangers.

Certified Safety Features in Modern Equipment

Today’s mining gear comes with approved safety elements that meet national and global standards. “The cab and commuter vehicle carriage have passed FOPS and ROPS standard testing certification, offering protection for drivers and riders.” These approvals ensure the equipment can endure tough conditions while keeping personnel safe.

Types of Underground Mining Equipment and Their Safety Features

Loaders and Haulers: Moving Minerals Securely

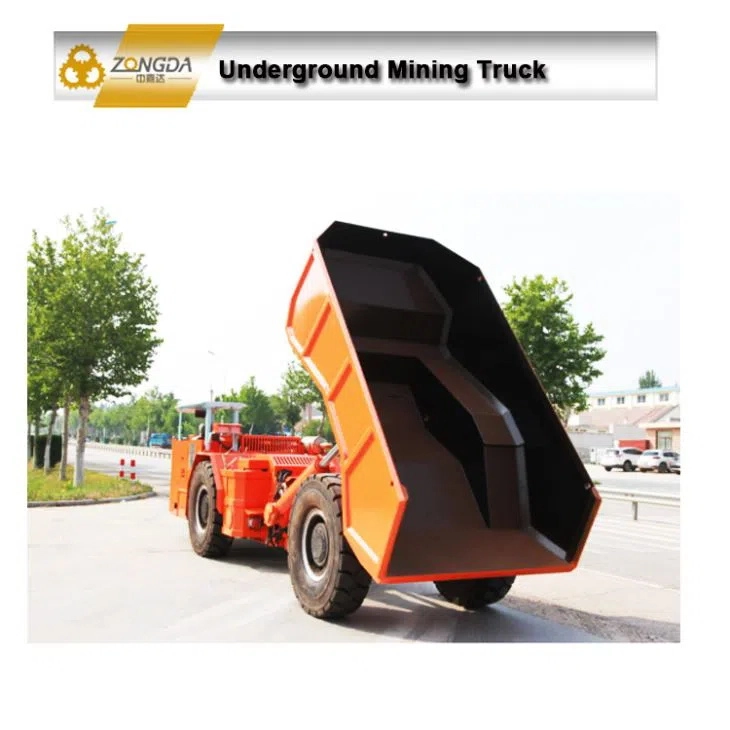

Loaders and haulers are crucial for shifting minerals safely within mines. “The machine can dig, load, move, and unload in one process. It has a compact build, easy handling, and efficient performance for mine recovery.” These units are crafted to manage heavy weights while maintaining steadiness andcontrol during transport.

Drilling and Excavation Machinery: Guaranteeing Safe Use

Drilling and excavation tools need precise handling to ensure safety. “Our company follows the growth plan of ‘overall tracking, partial exceeding, critical advancement.’” This method guarantees that drilling gear keeps evolving to meet safety needs.

Inspection Tools: Drones and Wearable Devices

Inspection aids like drones and wearable devices have transformed safety checks in mines. They deliver real-time updates on mine conditions. Workers avoid exposure to risks. By using these tools, mining firms can tackle safety issues ahead of time.

Addressing Common Safety Concerns in Underground Mining Operations

Lowering Risks Tied to Diesel Exhaust Fumes

Diesel exhaust fumes create serious health threats for miners. “The exhaust setup includes an imported purifier water filtration system, sharply cutting air pollution.” Using systems that reduce emissions shields miners from breathing problems linked to long-term diesel exposure.

Boosting Miner Safety with Training and Guidelines

Training efforts are essential for improving miner safety. They provide workers with the know-how to use equipment securely. “Customer satisfaction and success are our goals.” By focusing on training rules that put worker safety first, mining firms can build a culture of alertness among staff.

QINGDAO ZONGDA MACHINERY CO., LTD underground mining equipments Customization Service provides tailored options. These prioritize safety without sacrificing efficiency or output.

Innovations Shaping the Future of Mining Equipment Safety

Automation and Robotics: Changing Underground Work

Automation and robotics are reshaping underground mining tasks. They improve safety and productivity. These systems enable remote equipment handling. This reduces the need for miners to enter risky zones. “ZJTP mining winch is mainly used for mine floor shafts and inclined shaft lifting materials, personnel, and equipment.” This shows how automated tools blend into standard mining work, ensuring safer processes.

Wearable Devices: Live Monitoring and Warnings

Wearable devices play a big role in tracking miner health and surroundings in real time. Gadgets with sensors monitor vital signs and spot harmful gases. They send instant alerts to miners and control hubs. These advances allow quick reactions to possible threats, strengthening underground safety. “Inspection tools like drones and wearable technologies have revolutionized how safety inspections are conducted in mines.” Using such progress helps firms address safety proactively.

Challenges Faced by Manufacturers in Applying Safety Measures

Weighing Cost Against Advanced Safety Features

Mining equipment makers struggle to balance cost with high-end safety additions. Adding top-tier tech boosts safety but often raises production expenses. Manufacturers must find ways to include these features without making gear too costly for mining firms. “The power system uses Cummins or Deutz with lower emissions.” This reflects efforts to add eco-friendly tech while keeping costs in check.

Tackling Design Challenges for Better Safety

Design hurdles challenge makers aiming to improve equipment safety. Building machines that endure harsh underground settings while protecting operators demands creative engineering fixes. Makers must keep refining designs to match changing safety rules and work needs. “The driving and control system adopts a reasonable ergonomic layout design, sealed air-conditioned cab, and centralized control design configuration.” These design choices ensure gear is safe and easy to use.

FAQs

What part do mining equipment manufacturers play in protecting miners?

Mining equipment makers craft machines with cutting-edge safety traits to shield workers from risks.

How do new technologies boost the safety of underground mining gear?

Tools like ergonomic layouts and unified control systems enhance work efficiency while reducing hazards.

What steps are taken to cut diesel exhaust fumes in mines?

Mining firms use exhaust systems with purifiers to lessen harmful diesel engine emissions.

Why is training key for miner safety?

Training gives miners vital skills to handle machinery safely. It reduces accident rates in mines.

What inspection tools help ensure mine safety?

Drones and wearable devices offer real-time data on mine conditions. They keep workers out of harm’s way.