Understanding Mechanical Ventilation Systems in Tunnels

The Purpose and Importance of Ventilation in Tunnels

Mechanical ventilation systems are vital for keeping air fresh and safe inside tunnels. These setups handle airflow, clear out harmful gases, and manage heat. This makes the space safe for cars and walkers alike. In tunnels with car fumes piling up, good ventilation stops toxic gases like carbon monoxide and nitrogen oxides from stacking. Plus, if a fire breaks out, these systems steer smoke away. They keep escape paths clear and help firefighting crews.

Key Components of Tunnel Ventilation Systems

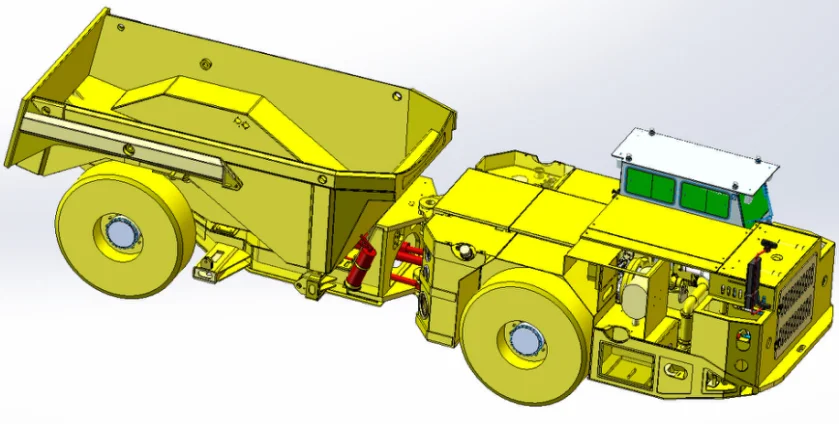

Tunnel ventilation systems have several main pieces that team up for smooth running. Fans lead the pack, pushing air through the tunnel. The overall structure of the Ventilation Fan includes blades, a motor, and a casing built tough for high-pressure spots. Ducts spread air evenly across the tunnel. Dampers tweak airflow paths and amounts. Sensors watch air quality and spot shifts in heat or gas levels. They let the system adjust on its own to keep things just right.

Factors Influencing the Efficiency of Tunnel Ventilation Systems

Airflow Management and Distribution

Handling airflow well is key to steady air quality in a tunnel. This means guiding speed and direction to whisk away pollutants fast. Good spread stops dead zones where bad gases might pile up. Smart control setups use live sensor data to tweak fan speeds and damper spots on the fly. This sharpens performance while cutting energy use.

Impact of Tunnel Length and Diameter on Ventilation Efficiency

A tunnel’s size shapes its ventilation needs a lot. Longer tunnels need stronger fans or extra air shafts to keep airflow solid over big stretches. Wider tunnels call for more air volume to mix pollutants evenly. Engineers must craft systems fit for each tunnel’s exact size to keep things running sharp.

Role of Environmental Conditions in System Performance

Outside factors like heat, wet air, and height also sway tunnel ventilation efficiency. Hot weather can strain fan motors more. High dampness might spark water buildup in ducts, slowing things over time. At high spots, thinner air cuts fan power. This needs tweaks in system build or running to adjust.

Types of Mechanical Ventilation Systems for Tunnels

Longitudinal Ventilation Systems

Longitudinal ventilation systems are a go-to for road tunnels thanks to their ease and low cost. They use jet fans set along the tunnel to push air one way, clearing pollutants straight to exhaust points. They shine in short-to-mid-length tunnels where air drag stays low.

Transverse Ventilation Systems

Transverse ventilation systems split fresh air in and dirty air out through separate paths. Fresh air comes via ducts on one side. Polluted air gets pulled out through ducts on the other. This setup ensures even air spread but needs trickier build work than longitudinal types.

Semi-Transverse Ventilation Systems

Semi-transverse systems mix bits of both longitudinal and transverse styles. They pump fresh air through ducts while using natural or fan-driven ways for exhaust. This blend gives wiggle room for specific ventilation hurdles but might cost more to set up.

Innovations in Tunnel Mechanical Ventilation Technology

Advanced Filtration Technologies for PM2.5 Control

Adding cutting-edge filtration tech to tunnel mechanical ventilation systems has shaken up air quality care. These setups nab tiny bits like PM2.5—stuff that’s risky to breathe in over time. High-efficiency particulate air (HEPA) filters and electrostatic precipitators are popping up more in these systems to boost their cleaning power. By grabbing tiny specks from the air, these tools keep tunnels cleaner for travelers and upkeep crews.

Plus, modern filter units come with self-cleaning tricks. These cut upkeep needs and stretch filter life. This tweak lifts running efficiency and trims downtime. It’s a budget-smart fix for long-haul tunnel management.

Integration of Smart Sensors for Real-Time Monitoring

Weaving smart sensors into mechanical ventilation systems has upped their game and quick response. These sensors keep tabs on stuff like air quality, heat, dampness, and gas levels in the tunnel space. They send live data. This lets the system tweak fan speeds and airflow paths on its own to keep things top-notch.

Say sensors spot high carbon monoxide or nitrogen oxides. They can kick ventilation up fast to scatter pollutants well. Also, smart analytics tied to artificial intelligence (AI) can guess when systems might hiccup or slack based on sensor trends. This sets up forward-thinking upkeep steps.

Smart sensors also shine in emergencies like fires. They guide the system to manage smoke flow and keep escape routes open. This live flexibility ensures safety and energy savings in tunnel work.

Use of Renewable Energy Sources in Ventilation Systems

As green goals grow worldwide, tapping renewable energy for mechanical ventilation systems is picking up steam. Solar panels and wind turbines power fans and other bits in tunnel ventilation setups. These green picks cut reliance on fossil fuels. They also trim running costs over time.

Energy storage tools like batteries make this greener shift work better. They stash extra power from peak times for use when output dips. This keeps energy steady while softening planet harm.

Some sharp systems even grab power from cars’ regenerative braking as they roll through tunnels. This recycled energy feeds back into the ventilation setup. It’s a fresh take that builds a greener tunnel model.

Selecting the Most Efficient Mechanical Ventilation System for Specific Tunnel Applications

Criteria for Choosing a Suitable System Based on Tunnel Design

Picking the sharpest mechanical ventilation system takes close looks at tunnel design factors. Big points include tunnel length, width, traffic load, and use type—like cars or walkers. For example:

- Longitudinal Ventilation Systems:Great for short-to-mid tunnels where one-way airflow handles pollutants fine.

- Transverse Ventilation Systems:Fit for longer tunnels needing even air spread across zones.

- Semi-Transverse Systems:Best for tunnels with odd challenges needing a mix of fresh air push and natural or fan-driven exhaust.

Engineers must also weigh build limits like room for ducts and fan setups when crafting these systems.

Balancing Efficiency, Cost, and Environmental Impact

Hitting a sweet spot between efficiency, cost, and planet care is key when picking a mechanical ventilation system for tunnels. High-efficiency setups might cost more upfront but often save cash long-term via lower energy use and upkeep bills.

Green concerns weigh big in choices too. Systems using renewable energy or top-tier filtration tech help sustainability aims. They also meet tough green rules.

To max out return on investment (ROI), folks should run full lifecycle cost checks. These cover startup costs (CAPEX), running costs (OPEX), and savings from energy-smart designs or green project perks from governments.

The overall structure of the Ventilation Fan—including its blades, motor, and casing built for high-stress spots—shows how engineering leaps can lift performance and toughness in tough tunnel settings.

Frequently Asked Questions

What is the purpose of integrating smart sensors into tunnel mechanical ventilation systems?

They track air quality and other bits live in tunnels. They tweak the system on its own to keep things running sharp.

How do advanced filtration technologies benefit tunnel environments?

They boost air quality by nabbing tiny bits like PM2.5 with HEPA filters or electrostatic precipitators. They cut upkeep needs with self-cleaning tricks too.

Why is renewable energy important in modern mechanical ventilation systems?

It cuts fossil fuel use, trims running costs over time, and backs green growth with picks like solar panels or car braking power.

Which factors should be considered when choosing a suitable ventilation system for tunnels?

Key bits include tunnel length, width, traffic load, use type (cars/walkers), build limits, efficiency needs versus cost, and planet impact.

Where can I find customized solutions tailored specifically to unique tunnel requirements?

QINGDAO ZONGDA MACHINERY CO., LTD offers custom services shaped to fit varied needs with exact-crafted bits aimed at lifting tunnel work efficiency worldwide!